爱华AIWA HV-FX780NH放像机电路图

)

)

)

)

)

)

)

)

)

)

VIDEO CASSETTE RECORDER

HV-FX780

S/M Code No. 09-999-335-6R1

NH

SERVICE MANUAL

DATA

BASIC TAPE MECHANISM : D-33 (6721R-0122A)

REVISION

This Service Manual is the “Revision Publishing” and replaces “Simple Manual”

(S/M Code No.09-999-335-6T1).

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

2

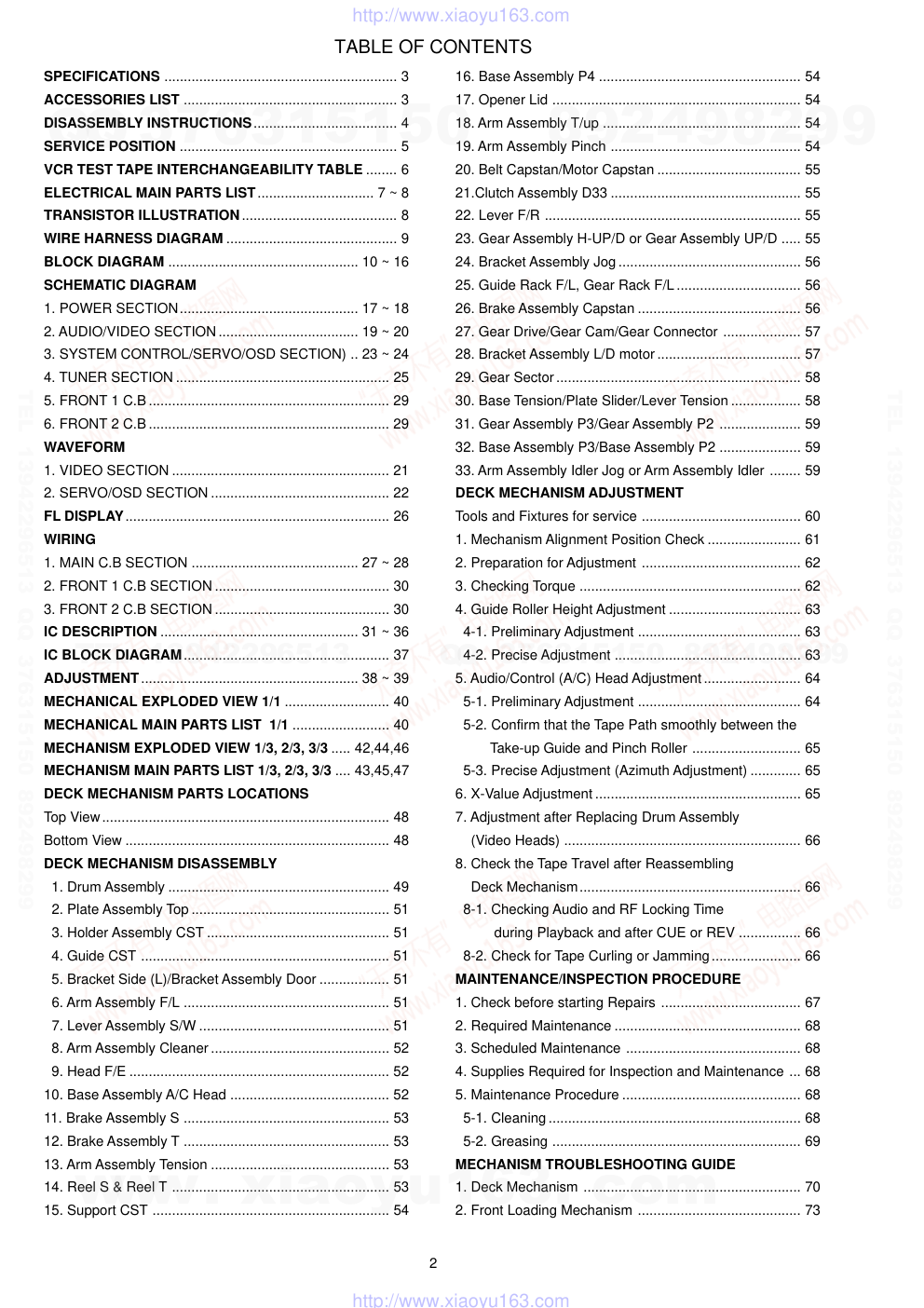

TABLE OF CONTENTS

SPECIFICATIONS ............................................................ 3

ACCESSORIES LIST ....................................................... 3

DISASSEMBLY INSTRUCTIONS..................................... 4

SERVICE POSITION ........................................................ 5

VCR TEST TAPE INTERCHANGEABILITY TABLE ........ 6

ELECTRICAL MAIN PARTS LIST.............................. 7 ~ 8

TRANSISTOR ILLUSTRATION........................................ 8

WIRE HARNESS DIAGRAM ............................................ 9

BLOCK DIAGRAM ................................................. 10 ~ 16

SCHEMATIC DIAGRAM

1. POWER SECTION.............................................. 17 ~ 18

2. AUDIO/VIDEO SECTION .................................... 19 ~ 20

3. SYSTEM CONTROL/SERVO/OSD SECTION) .. 23 ~ 24

4. TUNER SECTION ....................................................... 25

5. FRONT 1 C.B .............................................................. 29

6. FRONT 2 C.B .............................................................. 29

WAVEFORM

1. VIDEO SECTION ........................................................ 21

2. SERVO/OSD SECTION .............................................. 22

FL DISPLAY.................................................................... 26

WIRING

1. MAIN C.B SECTION ........................................... 27 ~ 28

2. FRONT 1 C.B SECTION ............................................. 30

3. FRONT 2 C.B SECTION ............................................. 30

IC DESCRIPTION ................................................... 31 ~ 36

IC BLOCK DIAGRAM..................................................... 37

ADJUSTMENT........................................................ 38 ~ 39

MECHANICAL EXPLODED VIEW 1/1 ........................... 40

MECHANICAL MAIN PARTS LIST 1/1 ......................... 40

MECHANISM EXPLODED VIEW 1/3, 2/3, 3/3 ..... 42,44,46

MECHANISM MAIN PARTS LIST 1/3, 2/3, 3/3 .... 43,45,47

DECK MECHANISM PARTS LOCATIONS

Top View.......................................................................... 48

Bottom View .................................................................... 48

DECK MECHANISM DISASSEMBLY

1. Drum Assembly ......................................................... 49

2. Plate Assembly Top ................................................... 51

3. Holder Assembly CST ............................................... 51

4. Guide CST ................................................................ 51

5. Bracket Side (L)/Bracket Assembly Door .................. 51

6. Arm Assembly F/L ..................................................... 51

7. Lever Assembly S/W ................................................. 51

8. Arm Assembly Cleaner .............................................. 52

9. Head F/E ................................................................... 52

10. Base Assembly A/C Head ......................................... 52

11. Brake Assembly S ..................................................... 53

12. Brake Assembly T ..................................................... 53

13. Arm Assembly Tension .............................................. 53

14. Reel S & Reel T ........................................................ 53

15. Support CST ............................................................. 54

16. Base Assembly P4 .................................................... 54

17. Opener Lid ................................................................ 54

18. Arm Assembly T/up ................................................... 54

19. Arm Assembly Pinch ................................................. 54

20. Belt Capstan/Motor Capstan ..................................... 55

21.Clutch Assembly D33 ................................................. 55

22. Lever F/R .................................................................. 55

23. Gear Assembly H-UP/D or Gear Assembly UP/D ..... 55

24. Bracket Assembly Jog ............................................... 56

25. Guide Rack F/L, Gear Rack F/L ................................ 56

26. Brake Assembly Capstan .......................................... 56

27. Gear Drive/Gear Cam/Gear Connector .................... 57

28. Bracket Assembly L/D motor ..................................... 57

29. Gear Sector ............................................................... 58

30. Base Tension/Plate Slider/Lever Tension .................. 58

31. Gear Assembly P3/Gear Assembly P2 ..................... 59

32. Base Assembly P3/Base Assembly P2 ..................... 59

33. Arm Assembly Idler Jog or Arm Assembly Idler ........ 59

DECK MECHANISM ADJUSTMENT

Tools and Fixtures for service ......................................... 60

1. Mechanism Alignment Position Check ........................ 61

2. Preparation for Adjustment ......................................... 62

3. Checking Torque ......................................................... 62

4. Guide Roller Height Adjustment .................................. 63

4-1. Preliminary Adjustment .......................................... 63

4-2. Precise Adjustment ................................................ 63

5. Audio/Control (A/C) Head Adjustment ......................... 64

5-1. Preliminary Adjustment .......................................... 64

5-2. Confirm that the Tape Path smoothly between the

Take-up Guide and Pinch Roller ............................ 65

5-3. Precise Adjustment (Azimuth Adjustment) ............. 65

6. X-Value Adjustment ..................................................... 65

7. Adjustment after Replacing Drum Assembly

(Video Heads) ............................................................. 66

8. Check the Tape Travel after Reassembling

Deck Mechanism......................................................... 66

8-1. Checking Audio and RF Locking Time

during Playback and after CUE or REV ................ 66

8-2. Check for Tape Curling or Jamming....................... 66

MAINTENANCE/INSPECTION PROCEDURE

1. Check before starting Repairs .................................... 67

2. Required Maintenance ................................................ 68

3. Scheduled Maintenance ............................................. 68

4. Supplies Required for Inspection and Maintenance ... 68

5. Maintenance Procedure .............................................. 68

5-1. Cleaning ................................................................. 68

5-2. Greasing ................................................................ 69

MECHANISM TROUBLESHOOTING GUIDE

1. Deck Mechanism ........................................................ 70

2. Front Loading Mechanism .......................................... 73

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

3

REF. NO

PART NO.

KANRI

DESCRIPTION

NO.

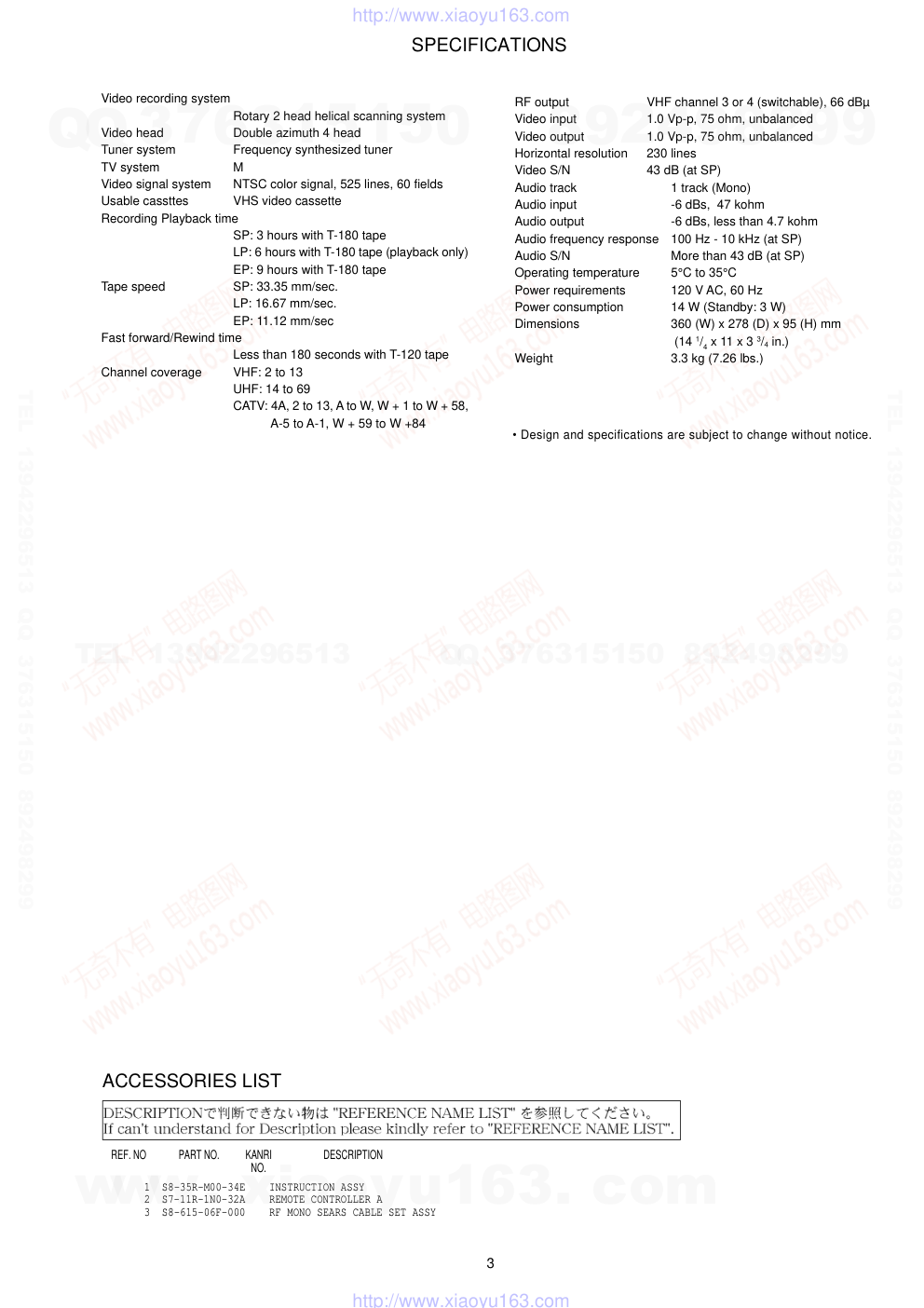

ACCESSORIES LIST

1 S8-35R-M00-34E INSTRUCTION ASSY

2 S7-11R-1N0-32A REMOTE CONTROLLER A

3 S8-615-06F-000 RF MONO SEARS CABLE SET ASSY

SPECIFICATIONS

• Design and specifications are subject to change without notice.

Video recording system

Rotary 2 head helical scanning system

Video head

Double azimuth 4 head

Tuner system

Frequency synthesized tuner

TV system

M

Video signal system

NTSC color signal, 525 lines, 60 fields

Usable cassttes

VHS video cassette

Recording Playback time

SP: 3 hours with T-180 tape

LP: 6 hours with T-180 tape (playback only)

EP: 9 hours with T-180 tape

Tape speed

SP: 33.35 mm/sec.

LP: 16.67 mm/sec.

EP: 11.12 mm/sec

Fast forward/Rewind time

Less than 180 seconds with T-120 tape

Channel coverage

VHF: 2 to 13

UHF: 14 to 69

CATV: 4A, 2 to 13, A to W, W + 1 to W + 58,

A-5 to A-1, W + 59 to W +84

RF output

VHF channel 3 or 4 (switchable), 66 dBµ

Video input

1.0 Vp-p, 75 ohm, unbalanced

Video output

1.0 Vp-p, 75 ohm, unbalanced

Horizontal resolution

230 lines

Video S/N

43 dB (at SP)

Audio track

1 track (Mono)

Audio input

-6 dBs, 47 kohm

Audio output

-6 dBs, less than 4.7 kohm

Audio frequency response

100 Hz - 10 kHz (at SP)

Audio S/N

More than 43 dB (at SP)

Operating temperature

5°C to 35°C

Power requirements

120 V AC, 60 Hz

Power consumption

14 W (Standby: 3 W)

Dimensions

360 (W) x 278 (D) x 95 (H) mm

(14 1/4 x 11 x 3 3/4 in.)

Weight

3.3 kg (7.26 lbs.)

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

4

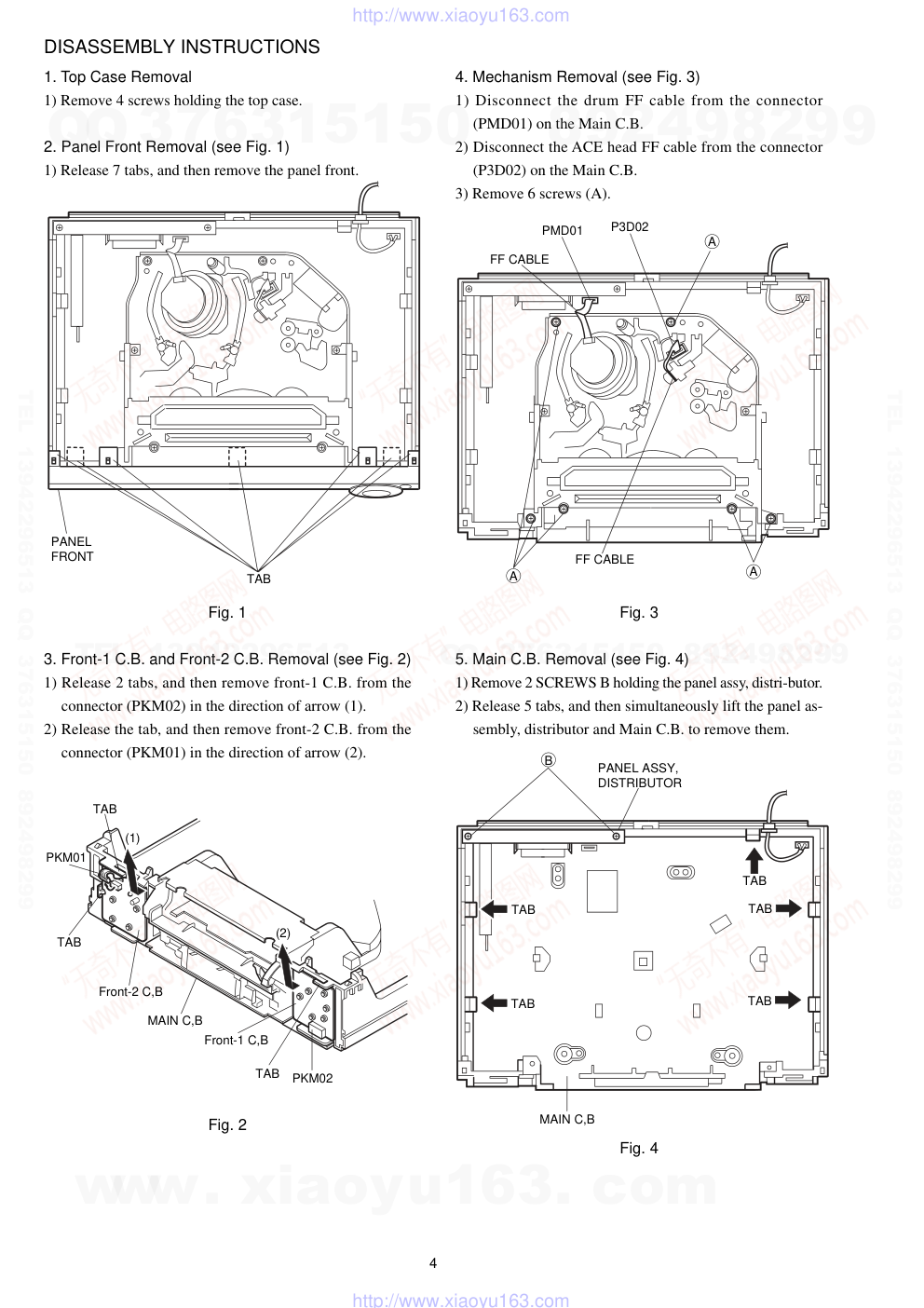

DISASSEMBLY INSTRUCTIONS

1. Top Case Removal

1) Remove 4 screws holding the top case.

2. Panel Front Removal (see Fig. 1)

1) Release 7 tabs, and then remove the panel front.

Fig. 1

3. Front-1 C.B. and Front-2 C.B. Removal (see Fig. 2)

1) Release 2 tabs, and then remove front-1 C.B. from the

connector (PKM02) in the direction of arrow (1).

2) Release the tab, and then remove front-2 C.B. from the

connector (PKM01) in the direction of arrow (2).

Fig. 2

4. Mechanism Removal (see Fig. 3)

1) Disconnect the drum FF cable from the connector

(PMD01) on the Main C.B.

2) Disconnect the ACE head FF cable from the connector

(P3D02) on the Main C.B.

3) Remove 6 screws (A).

Fig. 3

5. Main C.B. Removal (see Fig. 4)

1) Remove 2 SCREWS B holding the panel assy, distri-butor.

2) Release 5 tabs, and then simultaneously lift the panel as-

sembly, distributor and Main C.B. to remove them.

Fig. 4

TAB

PANEL

FRONT

PANEL ASSY,

DISTRIBUTOR

MAIN C,B

TAB

TAB

TAB

TAB

TAB

B

PKM02

TAB

TAB

TAB

(1)

(2)

PKM01

Front-1 C,B

Front-2 C,B

MAIN C,B

FF CABLE

FF CABLE

PMD01

P3D02

A

A

A

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

5

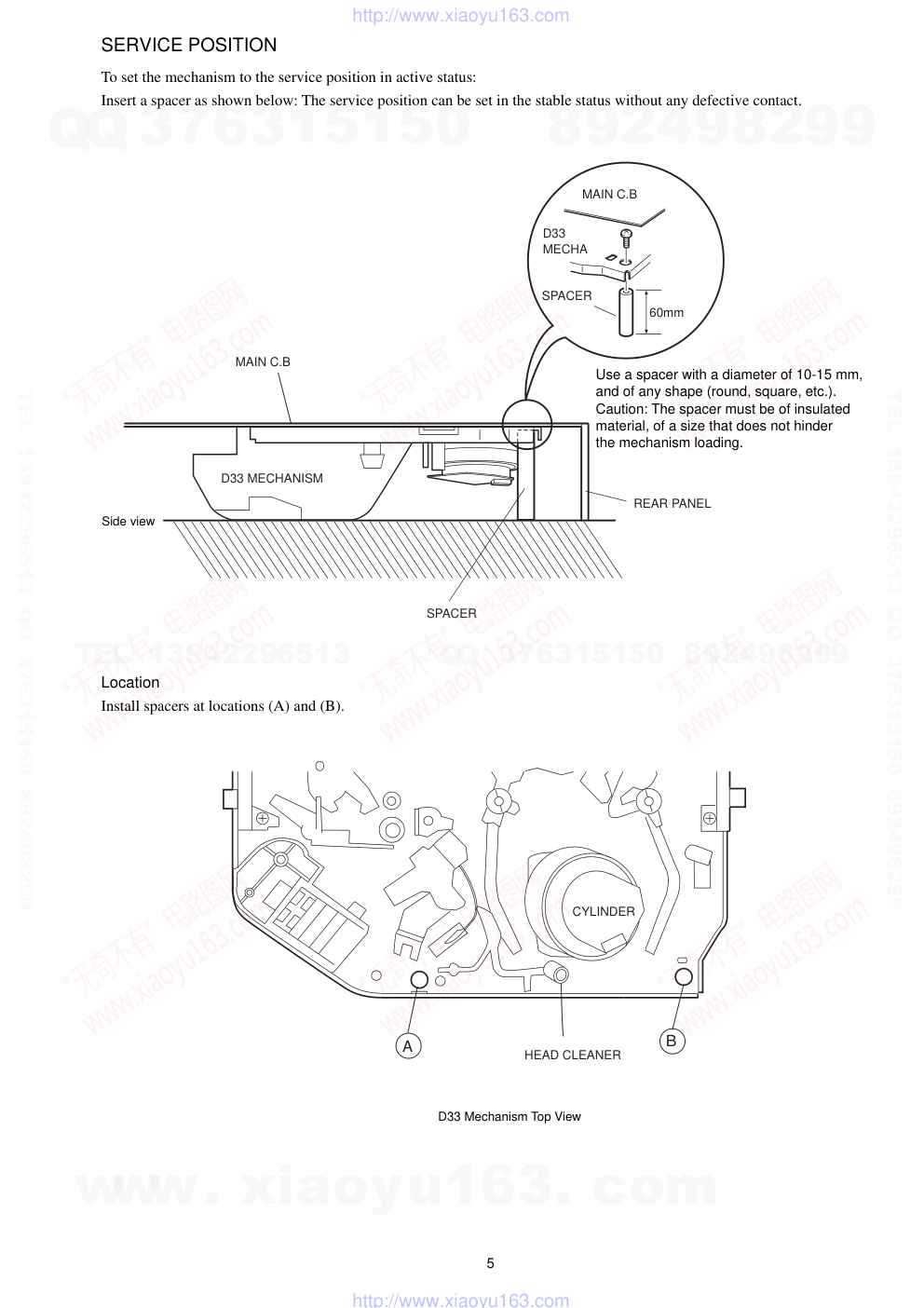

SERVICE POSITION

To set the mechanism to the service position in active status:

Insert a spacer as shown below: The service position can be set in the stable status without any defective contact.

Location

Install spacers at locations (A) and (B).

MAIN C.B

D33 MECHANISM

SPACER

60mm

MAIN C.B

D33

MECHA

SPACER

REAR PANEL

Use a spacer with a diameter of 10-15 mm,

and of any shape (round, square, etc.).

Caution: The spacer must be of insulated

material, of a size that does not hinder

the mechanism loading.

Side view

A

B

CYLINDER

HEAD CLEANER

D33 Mechanism Top View

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

6

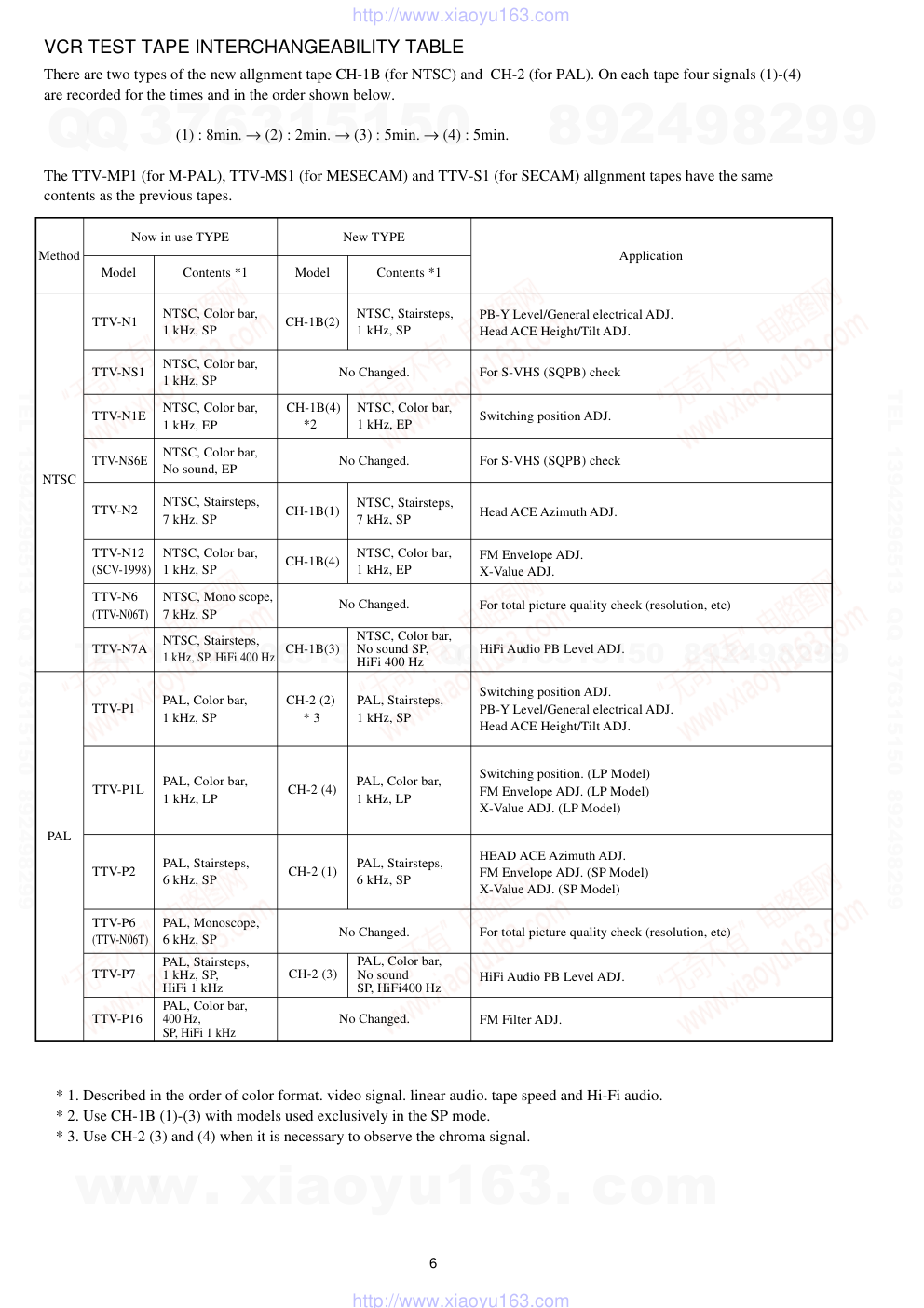

VCR TEST TAPE INTERCHANGEABILITY TABLE

There are two types of the new allgnment tape CH-1B (for NTSC) and CH-2 (for PAL). On each tape four signals (1)-(4)

are recorded for the times and in the order shown below.

(1) : 8min. → (2) : 2min. → (3) : 5min. → (4) : 5min.

The TTV-MP1 (for M-PAL), TTV-MS1 (for MESECAM) and TTV-S1 (for SECAM) allgnment tapes have the same

contents as the previous tapes.

Method

Now in use TYPE

Model

Contents *1

New TYPE

Model

Contents *1

Application

NTSC

PAL

TTV-N1

NTSC, Color bar,

1 kHz, SP

TTV-NS1

NTSC, Color bar,

1 kHz, SP

TTV-N1E

NTSC, Color bar,

1 kHz, EP

TTV-NS6E

NTSC, Color bar,

No sound, EP

TTV-N2

NTSC, Stairsteps,

7 kHz, SP

TTV-N12

(SCV-1998)

NTSC, Color bar,

1 kHz, SP

NTSC, Mono scope,

7 kHz, SP

TTV-N7A

NTSC, Stairsteps,

1 kHz, SP, HiFi 400 Hz

TTV-N6

(TTV-N06T)

TTV-P1

PAL, Color bar,

1 kHz, SP

TTV-P1L

PAL, Color bar,

1 kHz, LP

TTV-P2

PAL, Stairsteps,

6 kHz, SP

PAL, Monoscope,

6 kHz, SP

TTV-P6

(TTV-N06T)

TTV-P7

PAL, Stairsteps,

1 kHz, SP,

HiFi 1 kHz

TTV-P16

PAL, Color bar,

400 Hz,

SP, HiFi 1 kHz

CH-1B(2)

NTSC, Stairsteps,

1 kHz, SP

No Changed.

NTSC, Color bar,

1 kHz, EP

CH-1B(4)

*2

No Changed.

CH-1B(1)

NTSC, Stairsteps,

7 kHz, SP

CH-1B(4)

NTSC, Color bar,

1 kHz, EP

No Changed.

CH-1B(3)

NTSC, Color bar,

No sound SP,

HiFi 400 Hz

PAL, Stairsteps,

1 kHz, SP

CH-2 (2)

* 3

CH-2 (4)

PAL, Color bar,

1 kHz, LP

CH-2 (1)

PAL, Stairsteps,

6 kHz, SP

No Changed.

CH-2 (3)

PAL, Color bar,

No sound

SP, HiFi400 Hz

No Changed.

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

For S-VHS (SQPB) check

Switching position ADJ.

For S-VHS (SQPB) check

Head ACE Azimuth ADJ.

FM Envelope ADJ.

X-Value ADJ.

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

Switching position ADJ.

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

Switching position. (LP Model)

FM Envelope ADJ. (LP Model)

X-Value ADJ. (LP Model)

HEAD ACE Azimuth ADJ.

FM Envelope ADJ. (SP Model)

X-Value ADJ. (SP Model)

For total picture quality check (resolution, etc)

FM Filter ADJ.

HiFi Audio PB Level ADJ.

* 1. Described in the order of color format. video signal. linear audio. tape speed and Hi-Fi audio.

* 2. Use CH-1B (1)-(3) with models used exclusively in the SP mode.

* 3. Use CH-2 (3) and (4) when it is necessary to observe the chroma signal.

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

7

REF. NO

PART NO.

KANRI

DESCRIPTION

NO.

REF. NO

PART NO.

KANRI

DESCRIPTION

NO.

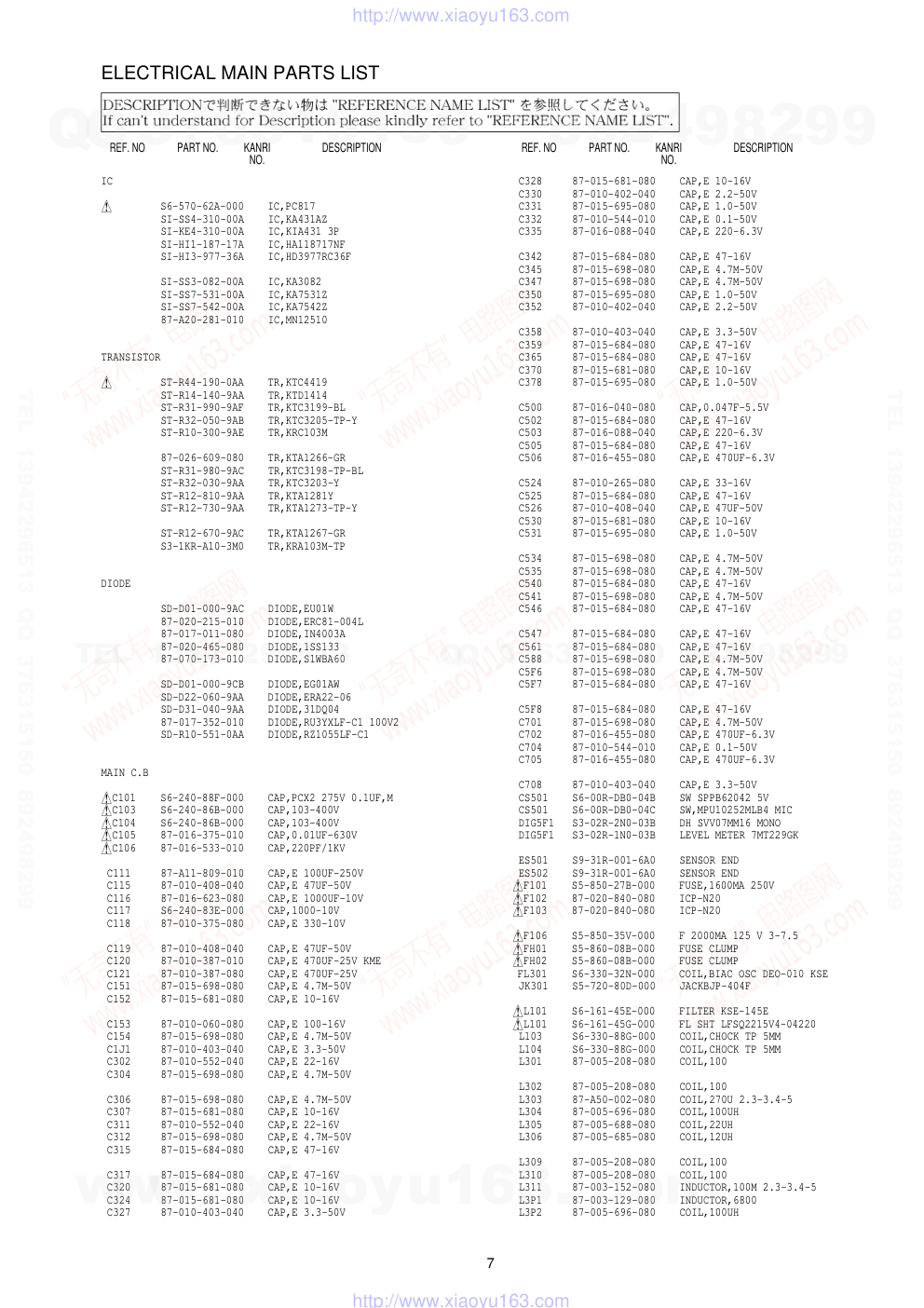

ELECTRICAL MAIN PARTS LIST

IC

!

S6-570-62A-000 IC,PC817

SI-SS4-310-00A IC,KA431AZ

SI-KE4-310-00A IC,KIA431 3P

SI-HI1-187-17A IC,HA118717NF

SI-HI3-977-36A IC,HD3977RC36F

SI-SS3-082-00A IC,KA3082

SI-SS7-531-00A IC,KA7531Z

SI-SS7-542-00A IC,KA7542Z

87-A20-281-010 IC,MN12510

TRANSISTOR

!

ST-R44-190-0AA TR,KTC4419

ST-R14-140-9AA TR,KTD1414

ST-R31-990-9AF TR,KTC3199-BL

ST-R32-050-9AB TR,KTC3205-TP-Y

ST-R10-300-9AE TR,KRC103M

87-026-609-080 TR,KTA1266-GR

ST-R31-980-9AC TR,KTC3198-TP-BL

ST-R32-030-9AA TR,KTC3203-Y

ST-R12-810-9AA TR,KTA1281Y

ST-R12-730-9AA TR,KTA1273-TP-Y

ST-R12-670-9AC TR,KTA1267-GR

S3-1KR-A10-3M0 TR,KRA103M-TP

DIODE

SD-D01-000-9AC DIODE,EU01W

87-020-215-010 DIODE,ERC81-004L

87-017-011-080 DIODE,IN4003A

87-020-465-080 DIODE,1SS133

87-070-173-010 DIODE,S1WBA60

SD-D01-000-9CB DIODE,EG01AW

SD-D22-060-9AA DIODE,ERA22-06

SD-D31-040-9AA DIODE,31DQ04

87-017-352-010 DIODE,RU3YXLF-C1 100V2

SD-R10-551-0AA DIODE,RZ1055LF-C1

MAIN C.B

!C101

S6-240-88F-000 CAP,PCX2 275V 0.1UF,M

!C103

S6-240-86B-000 CAP,103-400V

!C104

S6-240-86B-000 CAP,103-400V

!C105

87-016-375-010 CAP,0.01UF-630V

!C106

87-016-533-010 CAP,220PF/1KV

C111 87-A11-809-010 CAP,E 100UF-250V

C115 87-010-408-040 CAP,E 47UF-50V

C116 87-016-623-080 CAP,E 1000UF-10V

C117 S6-240-83E-000 CAP,1000-10V

C118 87-010-375-080 CAP,E 330-10V

C119 87-010-408-040 CAP,E 47UF-50V

C120 87-010-387-010 CAP,E 470UF-25V KME

C121 87-010-387-080 CAP,E 470UF-25V

C151 87-015-698-080 CAP,E 4.7M-50V

C152 87-015-681-080 CAP,E 10-16V

C153 87-010-060-080 CAP,E 100-16V

C154 87-015-698-080 CAP,E 4.7M-50V

C1J1 87-010-403-040 CAP,E 3.3-50V

C302 87-010-552-040 CAP,E 22-16V

C304 87-015-698-080 CAP,E 4.7M-50V

C306 87-015-698-080 CAP,E 4.7M-50V

C307 87-015-681-080 CAP,E 10-16V

C311 87-010-552-040 CAP,E 22-16V

C312 87-015-698-080 CAP,E 4.7M-50V

C315 87-015-684-080 CAP,E 47-16V

C317 87-015-684-080 CAP,E 47-16V

C320 87-015-681-080 CAP,E 10-16V

C324 87-015-681-080 CAP,E 10-16V

C327 87-010-403-040 CAP,E 3.3-50V

C328 87-015-681-080 CAP,E 10-16V

C330 87-010-402-040 CAP,E 2.2-50V

C331 87-015-695-080 CAP,E 1.0-50V

C332 87-010-544-010 CAP,E 0.1-50V

C335 87-016-088-040 CAP,E 220-6.3V

C342 87-015-684-080 CAP,E 47-16V

C345 87-015-698-080 CAP,E 4.7M-50V

C347 87-015-698-080 CAP,E 4.7M-50V

C350 87-015-695-080 CAP,E 1.0-50V

C352 87-010-402-040 CAP,E 2.2-50V

C358 87-010-403-040 CAP,E 3.3-50V

C359 87-015-684-080 CAP,E 47-16V

C365 87-015-684-080 CAP,E 47-16V

C370 87-015-681-080 CAP,E 10-16V

C378 87-015-695-080 CAP,E 1.0-50V

C500 87-016-040-080 CAP,0.047F-5.5V

C502 87-015-684-080 CAP,E 47-16V

C503 87-016-088-040 CAP,E 220-6.3V

C505 87-015-684-080 CAP,E 47-16V

C506 87-016-455-080 CAP,E 470UF-6.3V

C524 87-010-265-080 CAP,E 33-16V

C525 87-015-684-080 CAP,E 47-16V

C526 87-010-408-040 CAP,E 47UF-50V

C530 87-015-681-080 CAP,E 10-16V

C531 87-015-695-080 CAP,E 1.0-50V

C534 87-015-698-080 CAP,E 4.7M-50V

C535 87-015-698-080 CAP,E 4.7M-50V

C540 87-015-684-080 CAP,E 47-16V

C541 87-015-698-080 CAP,E 4.7M-50V

C546 87-015-684-080 CAP,E 47-16V

C547 87-015-684-080 CAP,E 47-16V

C561 87-015-684-080 CAP,E 47-16V

C588 87-015-698-080 CAP,E 4.7M-50V

C5F6 87-015-698-080 CAP,E 4.7M-50V

C5F7 87-015-684-080 CAP,E 47-16V

C5F8 87-015-684-080 CAP,E 47-16V

C701 87-015-698-080 CAP,E 4.7M-50V

C702 87-016-455-080 CAP,E 470UF-6.3V

C704 87-010-544-010 CAP,E 0.1-50V

C705 87-016-455-080 CAP,E 470UF-6.3V

C708 87-010-403-040 CAP,E 3.3-50V

CS501 S6-00R-DB0-04B SW SPPB62042 5V

CS501 S6-00R-DB0-04C SW,MPU10252MLB4 MIC

DIG5F1 S3-02R-2N0-03B DH SVV07MM16 MONO

DIG5F1 S3-02R-1N0-03B LEVEL METER 7MT229GK

ES501 S9-31R-001-6A0 SENSOR END

ES502 S9-31R-001-6A0 SENSOR END

!F101

S5-850-27B-000 FUSE,1600MA 250V

!F102

87-020-840-080 ICP-N20

!F103

87-020-840-080 ICP-N20

!F106

S5-850-35V-000 F 2000MA 125 V 3-7.5

!FH01

S5-860-08B-000 FUSE CLUMP

!FH02

S5-860-08B-000 FUSE CLUMP

FL301

S6-330-32N-000 COIL,BIAC OSC DEO-010 KSE

JK301 S5-720-80D-000 JACKBJP-404F

!L101

S6-161-45E-000 FILTER KSE-145E

!L101

S6-161-45G-000 FL SHT LFSQ2215V4-04220

L103 S6-330-88G-000 COIL,CHOCK TP 5MM

L104 S6-330-88G-000 COIL,CHOCK TP 5MM

L301 87-005-208-080 COIL,100

L302 87-005-208-080 COIL,100

L303 87-A50-002-080 COIL,270U 2.3-3.4-5

L304 87-005-696-080 COIL,100UH

L305 87-005-688-080 COIL,22UH

L306 87-005-685-080 COIL,12UH

L309 87-005-208-080 COIL,100

L310 87-005-208-080 COIL,100

L311 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L3P1 87-003-129-080 INDUCTOR,6800

L3P2 87-005-696-080 COIL,100UH

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

8

REF. NO

PART NO.

KANRI

DESCRIPTION

NO.

L501 87-005-208-080 COIL,100

L506 87-005-682-080 COIL,6.80UH

L701 87-005-693-080 COIL,56M K 6-6-5

LD501 S9-31R-001-7A0 LED

MS501 S6-00R-PY0-01B SW,MMS00420ZMBO MIC

P3D01 S5-612-34Y-000 CONN,6P

P3D02 S6-30R-5S0-08E CONN,6P

P3D03 S5-612-51B-000 CONN,2P

PMC01 S6-30R-2P0-05C CONN,8P

PMD01 S5-612-34V-000 CONN,7P

PMK01 S6-724-34B-000 CONN,5P

PMK02 S5-618-43J-000 CONN,10P

PML01 S6-30R-2S0-11A CONN,2P

!PW101

S5-612-92B-000 CONN,2P

!R101

S6-140-13C-000 RES,RCR50,2.2M J M15

!R102

S6-140-07K-000 RES,CEM 3.3-2W

!R104

SR-S33-02K-619 RES,M/F 33K-2W

!R105

SR-S12-00J-619 RES,M/F 120-1W

RC5F1 S7-12R-293-8GA REMOCON RECEIVER

RS501 S5-00R-AB0-02A SENSOR GP1S566

RS502 S5-00R-AB0-02A SENSOR GP1S566

SW701 S5-560-27C-000 SW,SLIDE

!T101

S6-420-21E-000 PT,KSE-021E

TU701 S7-00R-N3L-04A TUNER TADC-H002F

!V101

S6-560-04C-000 V SVC681D-10A

VR501 S6-130-32U-000 RES,VARIABLE (100K)

X301 S2-02R-135-71E X’TAL,3.579675MHZ

X301 S2-02R-135-71C X’TAL,3.579690MHZ

X501 S2-02R-110-0AC X’TAL,10MHZ

X501 S2-02R-110-0AE X’TAL,10MHZ 30PPM

X502 S5-290-01K-000 X’TAL,32.768KHZ

X502 S5-290-01B-000 X’TAL,32.768KHZ

X503 S2-02R-114-3AA X’TAL,14.317872

X503 S2-02R-114-3AC X’TAL,14.317872MHZ

X503 S2-02R-114-3AE X’TAL,14.317872MHZ

X5F1 S6-180-10B-000 X’TAL,4MHZ

ZD101 S9-7U0-3R3-1B0 ZENER,MTZ3.3B

ZD151 SD-Z13-000-9AC ZENER,MTZ13B

ZD152 87-070-334-070 ZENER,MTZ10B

ZD501 SM-TZ6-8CT-000 ZENER,MTZ6.8C

ZD502 83-NEG-677-080 DIODE,MTZ5.6B

ZD503 87-A40-476-010 ZENER,MTZ6.2A

ZD5F1 SD-Z51-000-9HA ZENER,MTZ5.1B 0.5W

ZD701 87-002-743-080 ZENER,MTZ33B

FRONT-1 C.B

PMK02 S5-618-44J-000 CONN,10P

SW5A1 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A2 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A3 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A4 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A5 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A6 S5-562-82C-000 SW,SKQNQED ALPS 5MM

FRONT-2 C.B

LD5A1 SD-L53-110-0AA LED,SG5311(GRN)

PMK01 S5-610-36D-000 CONN,5P

SW5A0 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A7 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A8 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A9 S5-562-82C-000 SW,SKQNQED ALPS 5MM

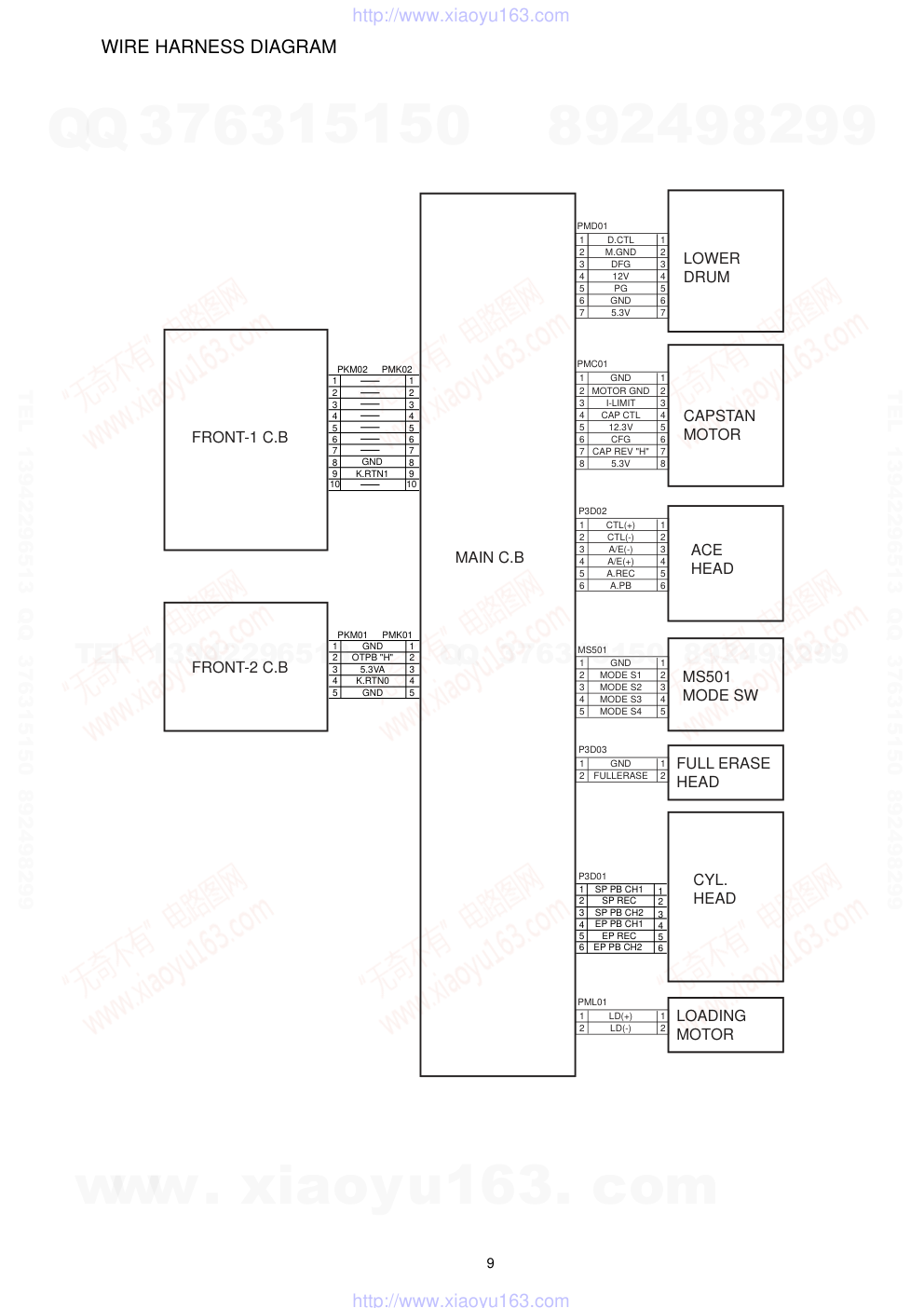

TRANSISTOR ILLUSTRATION

KRA103M

KRC103M

KTA1267

KTC3198

KTC3199

KTA1266

KTC3203

KTA1273

KTA1281

KTC3205

KTC4419

KTD1414

E C B

E C B

E C B

E C B

REF. NO

PART NO.

KANRI

DESCRIPTION

NO.

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

9

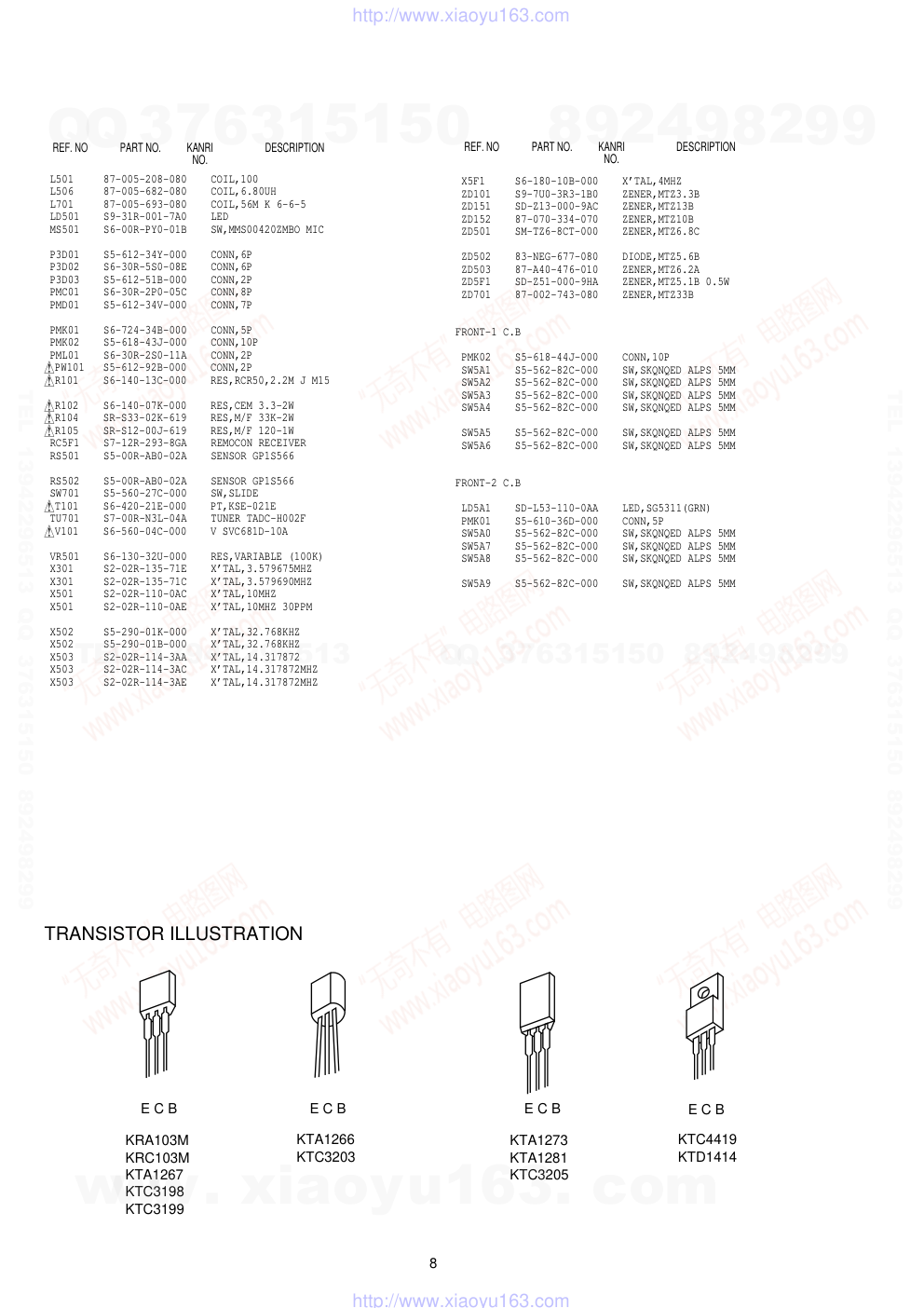

WIRE HARNESS DIAGRAM

1

2

3

4

5

6

7

D.CTL

M.GND

DFG

12V

PG

GND

5.3V

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

GND

MOTOR GND

I-LIMIT

CAP CTL

12.3V

CFG

CAP REV "H"

5.3V

1

2

3

4

5

6

7

8

1

2

3

4

5

6

CTL(+)

CTL(-)

A/E(-)

A/E(+)

A.REC

A.PB

1

2

3

4

5

6

1

2

3

4

5

GND

MODE S1

MODE S2

MODE S3

MODE S4

1

2

3

4

5

1

2

GND

FULLERASE

1

2

LOWER

DRUM

CAPSTAN

MOTOR

MS501

MODE SW

FULL ERASE

HEAD

CYL.

HEAD

MAIN C.B

FRONT-2 C.B

FRONT-1 C.B

ACE

HEAD

PMD01

PMC01

P3D02

MS501

P3D03

1

2

LD(+)

LD(-)

1

2 LOADING

MOTOR

PML01

P3D01

1

SP PB CH1

SP REC

SP PB CH2

2

3

4

5

6

1

2

3

4

5

6

EP PB CH1

EP PB CH2

EP REC

1

PKM01

GND

OTPB "H"

5.3VA

K.RTN0

GND

PMK01

2

3

4

5

1

2

3

4

5

1

PKM02

PMK02

2

3

4

5

6

7

1

2

3

4

5

6

7

8

8

GND

10

10

K.RTN1

9

9

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

10

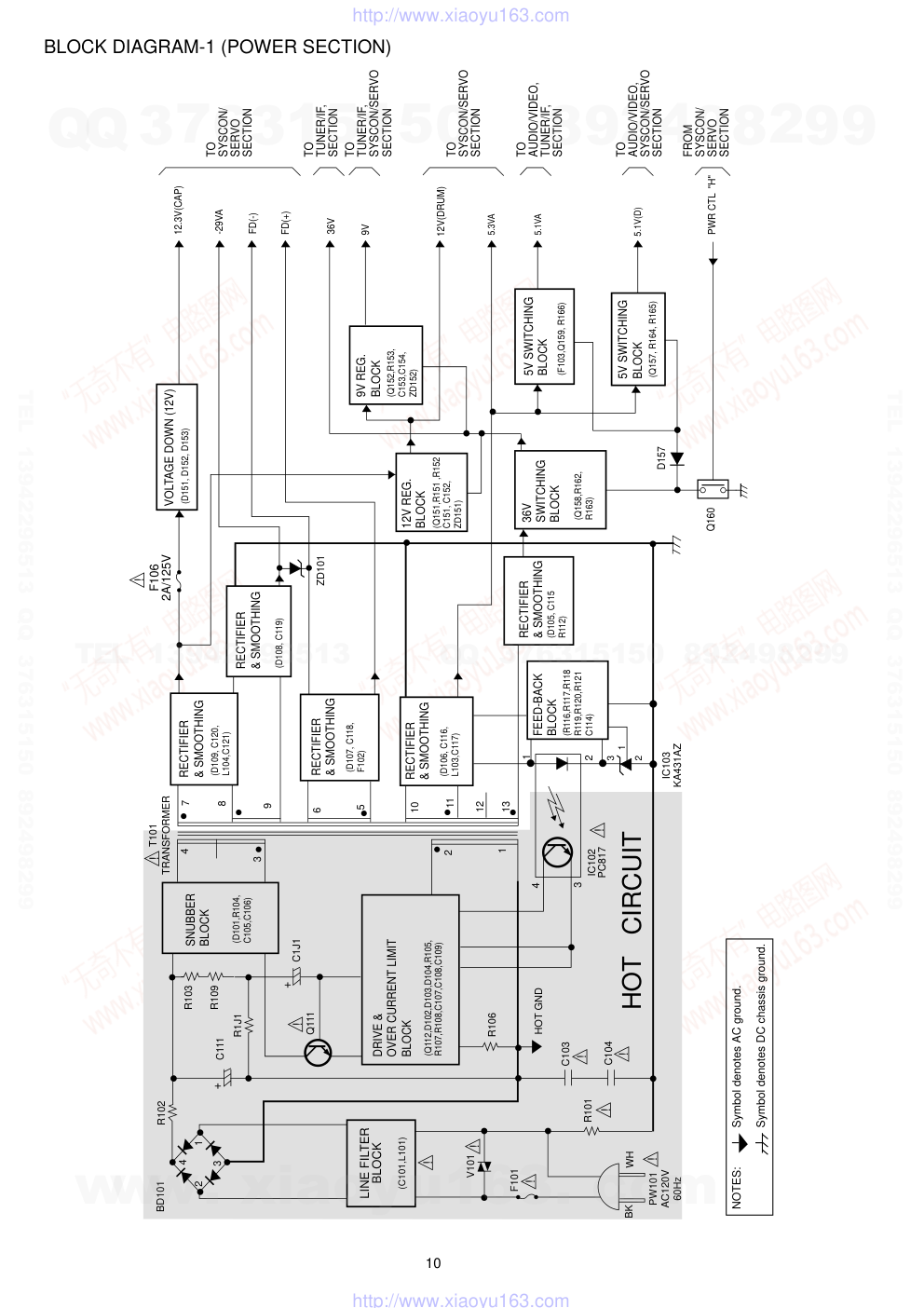

BLOCK DIAGRAM-1 (POWER SECTION)

NOTES:

Symbol denotes AC ground.

Symbol denotes DC chassis ground.

HOT CIRCUIT

BD101

R102

C111

R1J1

Q111

R106

C103

C104

R101

HOT GND

F101

V101

BK

WH

PW101

AC120V

60Hz

R103

R109

4

7

8

9

6

5

10

2

1

4

3

11

13

12

1

2

IC102

PC817

IC103

KA431AZ

3

T101

TRANSFORMER

4

2

3

1

(C101,L101)

LINE FILTER

BLOCK

RECTIFIER

& SMOOTHING

(Q152,R153,

C153,C154,

ZD152)

9V REG.

BLOCK

(Q151,R151 ,R152

C151, C152,

ZD151)

12V REG.

BLOCK

36V

SWITCHING

BLOCK

(D105, C115

R112)

RECTIFIER

& SMOOTHING

FEED-BACK

BLOCK

(R116,R117,R118

R119,R120,R121

C114)

RECTIFIER

& SMOOTHING

RECTIFIER

& SMOOTHING

DRIVE &

OVER CURRENT LIMIT

BLOCK

+

C1J1

+

12.3V(CAP)

-29VA

FD(-)

FD(+)

36V

9V

12V(DRUM)

5.1VA

5.3VA

5.1V(D)

SNUBBER

BLOCK

(Q112,D102,D103,D104,R105,

R107,R108,C107,C108,C109)

(D101,R104,

C105,C106)

(D107, C118,

F102)

(D109, C120,

L104,C121)

VOLTAGE DOWN (12V)

(D151, D152, D153)

(D106, C116,

L103,C117)

(Q158,R162,

R163)

5V SWITCHING

BLOCK

(Q157, R164, R165)

PWR CTL "H"

RECTIFIER

& SMOOTHING

(D108, C119)

ZD101

F106

2A/125V

5V SWITCHING

BLOCK

(F103,Q159, R166)

D157

Q160

FROM

SYSCON/

SERVO

SECTION

TO

SYSCON/SERVO

SECTION

TO

SYSCON/

SERVO

SECTION

TO

AUDIO/VIDEO,

TUNER/IF,

SECTION

TO

TUNER/IF,

SYSCON/SERVO

SECTION

TO

AUDIO/VIDEO,

SYSCON/SERVO

SECTION

TO

TUNER/IF,

SECTION

2

1

3

!

!

!

!

!

!

!

!

!

!

!

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

11

BLOCK DIAGRAM-2 (AUDIO SECTION)

T.A.IN

L.A.IN 1

9

8

7

VCA

DET

REC

AMP

AMP

PB EQ

AMP

4

11

2

AUDIO

REC/PB

HEAD

AUDIO

REC/PB

HEAD

AUDIO

ERASE

HEAD

:REC AUDIO SIGNAL

:PB AUDIO SIGNAL

17

A.OUT

17

A.IN

TU701

TUNER

JK301

AUDIO

IN

JK301

AUDIO

OUT

BIAS OSC

(FL301,Q301)

SW

(Q302,Q303)

SW

(Q304-Q306)

FULL

ERASE

HEAD

5.1V(D)

5.1V(D)

REC "H"

TO

SYSCON/SERVO

SECTION

IC301

HA118717NF

VIDEO/AUDIO

PROCESSOR

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

12

BLOCK DIAGRAM-3 (TUNER SECTION)

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SW701

CH

CH3

CH4

TU701

N.C

A.OUT

20

19

V.OUT

AFT

IF

N.C

30V

N.C

N.C

REG 5V

DATA

CLOCK

ENABLE

N.C

RF AGC

V.IN

CONTROL

REG 5V

CH S/W

A.IN

BUFFER

Q701

VIDEO

VCR 'H'

CLOCK

AFT

TU VIDEO

36V

5.1V(A)

DATA

TU AUDIO

MOD.A.IN

LINE VIDEO

VHF/UHF

IN FROM ANT

OUT TO TV

From

SYSCON/SERVO

SECTION

To/From

AUDIO/VIDEO

SECTION

From

POWER

SECTION

:REC AUDIO SIGNAL

:PB AUDIO SIGNAL

:REC VIDEO SIGNAL

:PB VIDEO SIGNAL

AFT: AUTOMATIC FREQUENCY CONTROL

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

14

13

BLOCK DIAGRAM-4 (VIDEO SECTION)

+

51

52

42

39

44

46

35

29

21

26

24

23

18

19

50

22

20

14

13

15

VIDEO IN

60

58

62

69

63

73

71

81

87

88

VIDEO

AGC

CLEAR

SYNC

V. OUT

D-V SYNC

Y-CCD

C-CCD

CLOCK Drive

6dB

AMP

FBC

Video ALC

SQUEL CH

C-SYNC

LPF

AGC DET

CLAMP

Y-LPF

YNR

CLAMP

SYNC

SEP

D.E.

C-LPF

SPF

ACC

C-LPF

NL Emph

LPF

LPF

HPF

VCA

TRAP

FBC

ALC

Main

Conv2

Main

Conv2

APC/ACC

DET

Main

Emph

FM

MOD

REC

Trap

REC-AMP

SP CH2

REC-AMP

SP CH1

MIX

ATT

B.E

C.K

CCD

LPF

L-DET

VCA

(-4dB)

f0=1.68M

f/0DEV

Adjst

X-tal

VCO/OSC

Serial Cont

interface

DATA

CLOCK

V.H/SW30

SP REC

+

+

51

42

39

44

14

13

62

69

63

81

89

84

IC301

HA118717NF

AUDIO/VIDEO

PROCESSOR

79

78

22

73

71

52

56

21

26

24

23

18

19

50

60

58

55

54

35

46

V. OUT

D-V SYNC

Y-CCD

C-CCD

CLOCK Drive

FBC

Video ALC

LPF

REC-AMP

SP CH1

DATA

CLOCK

V.H/SW30

V.ENV

SP PB CH2

SP PB CH1

Serial Cont

interface

X-tal

VCO/OSC

TRAP

FM AGC

P.EQ

G.EQ

D LIM

Y LPF

Main

De-Empf

DEMO

S LPF

2M LPF

ACC

CTL Trap

fh Trap

HIFI Trap

C LPF

DEALY

MIX

AMP

SQUEL CH

CLEAR

SYNC

CLAMP

CLAMP

Sharpness

CONTROL

YNR

NC

SYNC SEP

C-SYNC

NL

De-eMPH

VCA

C.K

LPF

BD

BPF

CCD LPF

APC/ACC

DET

L- DET

Main

Conv2

Main

Conv1

To/From

SYSCON/SERVO

SECTION

From

SYSCON/SERVO

SECTION

From

CYL.HEADS

X301

3.579MHz

X301

3.579MHz

From

SYSCON/SERVO

SECTION

To/From

SYSCON/SERVO

SECTION

From

TUNER/IF

SECTION

To/From

SYSCON/SERVO

SECTION

From

SYSCON/SERVO

SECTION

To

SYSCON/SERVO

SECTION

To

CYL.HEADS

87

88

REC-AMP

EP CH2

REC-AMP

EP CH1

EP REC

REC-AMP

SP CH2

86

94

REC-AMP

EP CH1

EP PB CH2

EP PB CH1

REC-AMP

EP CH2

91

SP

CH2

CH1

CH2

CH1

EP

ATT

-10dB

ATT

-10dB

ATT

-10dB

31

30

28

JK301

VIDEO

IN

:PB CHROMA SIGNAL

:PB Y SIGNAL

:REC CHROMA SIGNAL

:REC Y SIGNAL

:REC VIDEO SIGNAL

:PB VIDEO SIGNAL

IC301

HA118717NF

AUDIO/VIDEO

PROCESSOR

• PB MODE

• REC MODE

D LIM: Double Limit

FBC:

Feed Back Clamp

YNR:

Y Noise Reduction

APC:

Automatic Phase Control

ACC:

Automatic Color Control

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

16

15

BLOCK DIAGRAM-5 (SYSTEM CONTROL SECTION)

GND

MODE S1

MODE S2

MODE S3

MODE S4

MODE S/W

T-UP REEL

T-UP END

PML01

SUP REEL

(CST.SW)

5.1VD

CS501

5.3VA

5.3VA

ES501

R550

LD501

DECK IR LED

R553

R555

RS501

RS502

R556

Q514

Q515

R558

R548

C552

R5C6

C506

C501

C500

R542

D501

R541

R539

MS501

X501

10MHz

32.768KHz

OSC

OSC

X502

M

LD +

LD

2

1

L/D MOTOR

12V(DRUM)

R526

R525

5

6

4

7

8

1

10

Vcc 1

Vcc 2

OUT 1

OUT 2

GND

IN 2

IN 1

Vref

IC502

KA3082

LOADING MOTOR

DRIVE

C529

ZD501

2

1

2

RESET

Vcc

3

5.3VA

L501

5.3VA

9V

IC504

KA7531Z

RESET

+

+

C561

C521

+

C504

+C503

R516

R557

C536

SUP END

ES502

R564

C537

R544

OSC

R/C

PMK01

PMK01

4

RC5F1

TSOP1238SP1

REMOCON

SENSOR

L506

R517

C518

C519

OSC

X503

14.3178MHz

+

C532

C505

TO DECK

ZD502

ZD503

Q522

Q503

Q501

CV IN

77

76

75

74

1

5

57

4

17

34 35 36 37

22

41

16

IC501

HD3977RC36F

SYSCON/SERVO

PROCESSOR

MODE S1

I-Limit

MODE S2

MODE S3

MODE S4

T-UP Sensor

T-UP Reel

SUP Reel

CST IN

Vcc (SYSCON)

Vcc (SERVO)

CAP. PWM

CTL +

CTL -

DFG

CFG

CAP. RVS 'H'

CAP. ACCEL

DRUM ADJ.

V. ENV

V.H.SW30

C.Sync

DPG

D.V.Sync

72

73 OSC2

X1

X2

OSC1

70

69

53

52

50

fsc IN

13

KEY RTN 0

14

KEY RTN 1

fsc OUT

Dosc IN

19 LD -

LD +

20

31 32

38

40 61 80 81

12

24

87

26

39

27

25

78

DRUM PWM

42

Vcc (OSD)

3 SUP END Sensor

51

Dosc OUT

82

15

Vcc (A/D)

91

55

VCR 'H'

PLL DATA

PLL CLK

CV OUT

9

AFT

6

SQPB IN

90

45

POWER FAIL

89

A. MUTE 'H'

REC 'H'

79

62

43

54

C. sync (NOR)

C. sync

55

PWR CTL 'H'

2

Vcc

3

IIC DATA

IIC CLK

90

91

IC505

KA7542Z

POWER FAIL DET.

1

1

2

3

4

5

R

R

PKM02

PMK02

9

FRONT-2 C.B

FRONT-1 C.B

CTL.GAIN ADJ

CTL1

CTL2

CTL3

CTL OUT

CTL.

GAIN

ADJ

Q5J1

FROM

POWER

SECTION

TO/FROM

TUNER/IF

SECTION

TO

POWER

SECTION

TO

AUDIO/VIDEO

SECTION

1

2

3

4

1

2

3

4

1

SW5A7

CH UP

SW5A8

CH DOWN

SW5A0

OPTB

SW5A9

ONE-TOUCH

PLAYBACK

SW5A1

REC/ITR

SW5A2

REW

SW5A3

PLAY

SW5A4

F.FWD

SW5A5

STOP

SW5A6

PAUSE/

STILL

FLD ENV 94

FLD DATA OUT 97

FLD DATA IN

FLD CLK

96

95

1

P15

P16

NC

NC

G1

G2

G3

G4

G5

P3

P2

P1

POWER LED

SHUTTLE4

SHUTTLE3

SHUTTLE2

SHUTTLE1

DATA OUT

DATA IN

CLK

2

3

4

5

6

7

8

9 10 11

33 32 31 30 29 28 27 26 25 24 23

44

43

42

41

40

39

38

37

36

35

34 P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

12

13

14

15

16

17

18

19

20

21

22

G6

G7

G8

G9

VPP

IC5F1

MN12510

DISPLAY DRIVE

VDD

OSC1

OSC2

VSS

ENA

OSC

X5F1 4MHz

FD (+)

FD (-)

5.3VA

-29VA

FROM

POWER

SECTION

DIG5F1 DISPLAY

Q506

Q509

D502

R503

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

18

17

SCHEMATIC DIAGRAM-1 (POWER SECTION)

NOTES) Symbol denotes AC ground.

NOTES) Symbol denotes DC chassis ground.

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

MAIN (POWER SECTION) C.B

AC120V

60Hz

C101

0.1u/275V

ICP-N20

ICP-N20

(0.8A/50V)

12.3V(CAP)

To

AUDIO/VIDEO

SECTION

To

TUNER/IF

SECTION

Front

SYSCON/SERVO

SECTION

To

SYSCON/SERVO

SECTION

To

SYSCON/SERVO

SECTION

2

1

3

IC103

KA431AZ

(KIA431)

IC102

PC817

35.5

35.6

34.9

5.3

5.2

4.6

5.3

5.1

5.7

15.0

12.1

12.7

12.1

9.8

9.2

ONE VOLTAGE:PB OR REC MODE

: HOTCIRCUIT

*

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

20

19

SCHEMATIC DIAGRAM-2 (AUDIO/VIDEO SECTION)

VIDEO

AUDIO

IN

OUT

IN

OUT

From

POWER

SECTION

To/From

SYSCON/SERVO

SECTION

TU VIDEO

LINE VIDEO

From

TUNER/IF

SECTION

(1/6)

(1/4)

R

R

EMPH

VIDEO/AUDIO

PROCESSOR

(6/6)

(2/4)

(3/4)

(4/4)

To/From

SYSCON/SERVO

SECTION

SQPB IN

IN

(4/6)

(3/6)

(2/6)

809 MOD.A.IN

To/From

TUNER/IF

SECTION

(5/6)

3.5796MHz

X301

MAIN (AUDIO/VIDEO SECTION) C.B

TU AUDIO

VIDEO

5.1V(D)

5.1V(A)

2.5

2.5

0

0

0

0

2.5

0

2.8

2.5

2.5

2.5

2.5

2.5

5.0

1.6

(2.1)

1.6

(2.1) 2.3

-

(0)

1.8

(0)

2.1

2.8

2.8

2.1

2.2

(2.4)

2.8

2.1

1.4

2.1

0

2.8

1.9

2.8

-

-

0

0

0

2.7

2.7

1.7

5.1

5.1

5.1

5.1

5.1

2.5

0

0

0

0

-

-

-

2.8

1.9

2.1

2.8

-

2.8

2.8

2.8

5.0

-

-

-

2.3

(0)

5.0

5.0

0

2.5

2.5

2.1

2.2

2.1

-

(2.7)

2.1

-

-

2.8

2.1

(-)

-

1.9

-

1.1

-

-(0)

0

5.1

5.0

-

-

-

2.5

2.1(2.3)

2.1(2.3)

2.1(2.3)

2.1(2.3)

2.1(2.3)

2.1(2.3)

2.1(2.3)

2.1

(2.3)

0

(1.4)

1

2

3

3

3

4

5

6

7

8

9

9

10

11

12

12

12

12

13

13

13

13

0.3

(0.6)

0.3

(4.8)

0

0.3(4.5)

4.9

(4)

4.9

(0)

5.0

5.0

4.8

4.8

0

(4.8)

0

(4.8)

4.2

(4.8)

4.9

(-12.8)

0.7

(-13)

0

(-6.3)

0.7

(-13)

To

FULL ERASE

HEAD

To/From

ACE

HEADS

To/From

CYL.

HEADS

:REC Y SIGNAL

:REC CHROMA SIGNAL

:REC VIDEO SIGNAL

:PB VIDEO SIGNAL

:PB Y SIGNAL

:PB CHROMA SIGNAL

:PB AUDIO SIGNAL

:WAVE FORMS No.

:REC AUDIO SIGNAL

ONE VOLTAGE:PB OR REC MODE

TWO VOLTAGES:PB AND (REC) MODE

*

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

21

WAVEFORM-1 (VIDEO SECTION)

IC301 Pin $

100mV/10µsec DIV

VV/EE

(Main De-Emphasis out)

IC301 Pin ^

100mV/10µsec DIV

PB

(Main De-Emphasis

Peaking)

IC301 Pin *, ¡, £

100mV/10µsec DIV

VV/EE

Clamp Drive In Pin *

Y-out (to 1H CCD) Pin ¡

Y-out (from 1H CCD) Pin £

IC301 Pin ⁄

200mV/10µsec DIV

EE

(VIDEO IN)

IC301 Pin <

100mV/0.2msec DIV

REC/PB

(2fsc)

1

2

3

4

5

6

7

8

9

0

!

@

#

IC301 Pin 50

1.0mV/20µsec DIV

VV/EE

(C-SYNC OUT)

IC301 Pin 52

500mV/10µsec DIV

VV/EE

(VIDEO OUT)

IC301 Pin 54

220mV/20µsec DIV

PB

(C.OUT)

IC301 Pin 86 , 87 , 88 , 89

500mV/2msec DIV

SP REC

(REC RF)

IC301 Pin 78

100mV/5msec DIV

PB

(PB RF out)

IC301 Pin 71

100mV/0.2msec DIV

PB/REC

(3.58MHz X-TAL IN)

IC301 Pin 58 , 60

200mV/20µsec DIV

VV/EE

(from 1H CCD Pin 58

to 1H CCD Pin 60 )

IC301 Pin 91 , 92 , 93 , 94

500mV/2msec DIV

EP REC

(REC RF)

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

22

WAVEFORM-2 (SERVO/OSD SECTION)

IC501 Pin ≤

1V/5msec DIV

REC/PB

(V.H/SW)

IC501 Pin ≥

1V/2msec DIV

QUE/REV

(D.V-SYNC)

IC501 Pin ⁄

1V/10msec DIV

REC

(CTL+)

IC501Pin ¤

1V/10msec DIV

REC

(CTL–)

IC501 Pin °

1V/1msec DIV

REC/PB

(DFG)

IC501 Pin ·

1V/10µsec DIV

REC/PB

(DPG)

IC501 Pin .

500mV/10µsec DIV

EE/PB

(V-OUT)

IC501 Pin ‚

1V/1msec DIV

REC/PB

(CFG)

IC501 Pin ,

100mV/10µsec DIV

EE/PB

(V-IN)

1

2

3

4

5

6

7

8

9

0

IC501Pin 54

1V/20µsec DIV

EE/PB

(C-SYNC)

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

24

23

SCHEMATIC DIAGRAM-3 (SYSTEM CONTROL/SERVO/OSD SECTION)

1

2

4

3

5

6 7

8

9

10

IC502

KA3082

LOADING

MOTOR DRIVE

To

LOADING

MOTOR

To/From

AUDIO/VIDEO

SECTION

To/From

LOWER

DRUM

To/From

CAPSTAN

MOTOR

From

MODE SW

R

0

5.3

5.1

R

0

5.3

5.1

R

0.2

0.2

5.0

0

0

To

AUDIO/VIDEO

SECTION

GP1S566

GP1S566

R

IC504

KA7531Z

RESET

(2/3)

(2/3)

(3/3)

(3/3)

(6/13)

(1/3)

(2/3)

(1/3)

(3/3)

(2/3)

(8/13)

(11/13)

(2/3)

(3/3)

(8/13)

(7/13)

(2/5)

(1/3)

(1/5)

(13/13)

(4/5)

(5/5)

(12/13)

(3/5)

(9/13)

R

0

5.4

4.6

4.9

5.6

5.3

5.3

5.4

0.1

0

0.7

3.6

:WAVE FORMS No.

ONE VOLTAGE:PB OR REC MODE

TWO VOLTAGES:PB AND (REC) MODE

FLD: Fluorescence Drive

*

HD3977RC36F

IC501

SYSCON/SERVO

PROCESSOR

KA7542Z

POWER FAIL

DET.

X503

14.3178MHz

DISPLAY

DRIVE

RC5F1

TSOP1238SP1

REMOTE

SENSOR

(2/13)

(4/13)

(3/3)

14(3/3)

13(3/3)

(2/3)

(2/3)

(3/13)

K.RTN1

K.RTN0

From

FRONT-1 C.B

PKM02

To/From

FRONT-2 C.B

PMK01

IIC DATA

IIC CLOCK

(3/3)

(1/3)

(1/13)

(3/3)

IIC DATA

IIC CLOCK

SQPB IN

To/From

TUNER/IF

SECTION

To/From

AUDIO/

VIDEO

SECTION

To/From

POWER

SECTION

DISPLAY

MAIN (SYSCON/SERVO SECTION) C.B

(

(

VIDEO

30

6

6

5.1V(D)

C-SYNC “H”

0

0.9

2.9

1.8

1.8

12.2

12.2

0.9

0.4

(0.5)

0.4

(0.5)

0.4

0

0

0

0

4.5

4.5

0

5.1

5.0

0

5.2

0

5.0(0)

0

5.1

2.5

2.5

2.7

2.4

0

2.5

2.9

(2.3)

2.2

0

0.1

2.2

2.2

2.2

2.2

4.4

2.5

5.2

5.3

2.6

1.3

2.6

0

2.0

0

0

1.2

0

0

5.1

1.5

3.5

5.1

0.2(2.3)

2.3(4.2)

1.2(0)

2.4

2.4

0(0.4)

5.0

0

5.1

0

0

4.9(4.5)

5(0)

0

0

0

5.0

0.2

0

0

1.5

0.8

0

2.5

2.5

5.4

0

5.4

5.0

3.1

0

2.7

1.2

5.1

0

0

0

0

4.6

0

4.3

4.8

4.8

0

0

4.8

0(4.8)

4.8

4.8(0)

0

0

0

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

26

25

SCHEMATIC DIAGRAM-4 (TUNER SECTION)

CH4

CH

CH3

VHF/UHF

IN FROM ANT

OUT TO TV

TU VIDEO

TU AUDIO

LINE VIDEO

VIDEO

To/From

SYSCON/SERVO

SECTION

From

POWER

SECTION

To/From

AUDIO/VIDEO

SECTION

MAIN(TUNER/IF SECTION)C.B

ONE VOLTAGE:PB OR REC MODE

*

:REC AUDIO SIGNAL

:PB AUDIO SIGNAL

:REC VIDEO SIGNAL

:PB VIDEO SIGNAL

FL DISPLAY

• GRID ASSIGNMENT

• ANODE CONNECTION

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

E

F

G

H

I

J

28

27

WIRING-1 (MAIN C.B SECTION)

AC120V

60Hz

F101

R102

FH01

FH02

V101

C101

R101

L101

BD101

R1J1

R106

R109

B

C

E

E

C

B

1

3

4

5

7

9

11

13

1

2

3

4

IC102

ES501

E

C

B

B

C

E

ZD151

E

C

B

E

C

B

E

C

B

E

C

B

B

C

E

E

C

B

VR501

5

10

7

3

1

PMK02

5

3

1

MS501

7

1

8

2

PMC01

B

C

E

B

C

E

B

C

E

B

C

E

E

C

B

E

C

B

B

C

E

B

C

E

B

C

E

E

C

B

2

1

PML01

1

3

5

7

10

IC502

1

3

4

6

FL301

VR301

L301

R313

R312

1

5

6

2

P3D02

1

3

7

2

6

PMD01

5

1

10

15

20

25

30

51 55

60

65

70

75

80

31 35

40

45

50

81

85

90

95

100

IC301

1

5

2

6

P3D01

LD501

E

C

B

SW701

SW701

TU701

1

3

5

6

8

10

12

14

16

17

19

20

2

1

P3D03

ES502

B

C

E

E

C

B

B

C

E

PMK01

1

3

5

X502

CS501

1

5

10

15

20

25

30

51 55

60

65

70

75

80

31 35

40

45

50

81

85

90

95

100

IC501

1

3

2

4

RS502

E

C

B

B

C

E

E

C

B

B

C

E

1

5

11

23

30

33

34

40

44

22

15 12

IC5F1

B

C

E

1

3

2

4

RS501

X5F1

30

32

24

22

26

28

19

20

34

37

38

1

2

5

7

9

11

12

DIG5F1

1

3

RC5F1

RC5F1

(REMOTE SENSOR)

MS501

To MODE SW

DIG5F1

(DISPLAY)

CS501

(CST/TAP.SW)

VHF/UHF

AUDIO

CH

IN FORM ANT

IN

OUT

VIDEO

IN

OUT

OUT TO TV

P3D02

To

ACE HEADS

P3D01

To

CYL.

HEADS

PMD01

To

LOWER

DRUM

PMC01

To CAPSTAN

MOTOR

PML01

To LOADING

MOTOR

To

FRONT-1 C.B

PKM02

C107

D102

C1J1

Q111

C109

Q112

R105

D103

C103

D108

D105

C119

D106

D109

L103

D111

R164

R152

R151

R153

C154

ZD152

C152

R165

D157

R171

R166

R119

C509

C505

D107

F102

C5F6

C501

ZD503

R542

R578

R577

R576

R575

R5F9

R5F8

R5F5

R5G0

R5G1

R5G2

R5G3

R5G4

C5F8

C564

R568

C527

R519

R532

C524

C506

C531

Q531

R527

R559

C516

R5E7

C508

C511

C532

C556

C557

R5E8

R558

C596

C504

R518

R582

R5C6

X503

C590

R517

L506

C588

R509

R5J1

R5J2

R5J3

Q5J1

C502

C500

C701

C704

R706

R707

R708

R831

R710

R709

R512

R506

C347

C345

R332

C378

C358

C357

C353

R336

L311

C371

C372

C364

C363

C361

C362

C369

C368

L309

C365

L310

R301

C301

C302

R307

R335

R331

C354

R308

C313

R309

C314

Q301

R120

R121

R514

R526

R525

ZD501

C530

C526

C525

R528

R557

C536

C522

R523

R513

Q303

Q3J2

Q3J1

Q3J3

Q302

Q307

Q304

C114

R341

R340

C546

C528

C315

C320

R310

R5C5

C534

C533

F106

R311

L302

C316

R322

C324

C328

C335

L304

C334

L305

C341

C336

R329

C342

C340

C343

R330

C318

C321

C3J1

R3J1

L303

R325

R3J7

C319

R327

C323

C529

D151

D152

D153

R118

C312

C329

C370

R328

C3P2

L3P2

R342

L3P1

C3P1

C307

C305

C304

R339

R318

C306

C310

R306

R314

R315

R320

C309

R321

C308

R304

C303

R303

R302

C367

C366

C350

R333

C349

C352

R334

C351

C344

C346

L306

R531

C537

R570

R504

R564

R507

C535

R548

C562

C542

C523

Q509

Q5J2

R522

R5B1

R5F6

C581

R5B3

R560

R556

R5F7

D501

R162

C104

C108

R107

R108

D104

C111

R103

D101

C106

R104

T101

R111

C115

C116

C120

R112

C121

C117

Q158

Q159

Q160

R5F1

R5F2

R539

L502

C5F7

Q501

Q503

R581

C551

C544

R553

Q514

R508

R510

R501

R502

R521

R5G5

R5G6

ZD5F1

C5F4

R5H1

R5C9

R5B4

C582

R555

R547

R5B5

D502

R503

R550

R569

C584

R546

R505

C545

R563

C543

R543

R579

C512

C514

X501

C571

C570

C541

C519

C591

R599

R516

C518

R567

R544

L501

C521

C561

C503

C540

ZD502

R536

Q522

R511

IC505

Q506

R533

R580

C520

R5C7

ZD701

C703

C709

L701

C702

R830

Q701

JK301

C710

R703

R702

R711

R326

C331

C708

R323

C705

X301

C348

C360

C355

C322

C317

C311

R324

C326

C330

C332

C325

C338

C337

R338

C339

C333

C327

Q305

Q306

C359

R319

C548

R701

C510

C547

IC504

C515

R515

R534

C513

Q515

C507

C575

C574

C567

D5E5

R5G7

D5F4

R169

R5C1

R5C2

R5C3

R5C4

R541

Q157

R163

C153

C118

ZD101

L104

Q151

C151

Q152

C105

R117

R116

1

3

1

3

3

1

IC103

MAIN C.B

CH3

CH4

P3D03

To

FULL

ERASE

HEAD

PMK01

To

FRONT-2 C.B

PMK01

PW101

IC503

1

3

5

7

8

4

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

30

29

SCHEMATIC DIAGRAM-5 (FRONT-1 SECTION)

SCHEMATIC DIAGRAM-6 (FRONT-2 SECTION)

WIRING-2 (FRONT-1 C.B SECTION)

WIRING-3 (FRONT-2 C.B SECTION)

1

2

3

4

5

6

A

B

C

D

E

F

G

H

I

J

PKM01

Q5A1

LD5A1

C5A1

SW5A9

POWER

SW5A8

CH DOWN

SW5A7

CH UP

SW5A0

OPTB

R5A8

R5A9

R5A6

R5A7

1

5

B

C

E

FRONT-1 C.B

PKM02

SW5A3

PLAY

SW5A5

STOP

SW5A4

FF

SW5A1

REC

SW5A6

P/STILL

SW5A2

REW

5

1

10

R5A3

R5A4

R5A5

R5A1

R5A2

To

MAIN C.B

PMK02

FRONT-2 C.B

To

MAIN C.B

PKM01

R

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

GND

OTPB "H"

5.3VA

K. RTN 0

GND

PMK01

R5A9

120

LD5A1

SG5311

Q5A1

KRC103M

SW5A7

CH UP

SW5A8

CH DOWN

SW5A9

SW5A0

OPTB

SW5A6

SW5A5

SW5A4

SW5A3

SW5A2

SW5A1

R5A6

1.8K

R5A7

1.5K

R5A8

2.2K

R5A5

3.9K

R5A4

2.7K

R5A3

2.2K

R5A2

1.5K

R5A1

1.8K

GND

K.RTN 1

PKM02

FRONT-2 C.B

FRONT-1 C.B

To

MAIN C.B

SYSCON/SERVO

SECTION

PMK01

(

)

To

MAIN C.B

SYSCON/SERVO

SECTION

PMK02

(

)

REC/ITR

REW/

PLAY

/F FWD

STOP

PAUSE/

STILL

ONE-TOUCH

PLAYBACK

w w w

.

x i a o y u 1 6 3 .

c o m

Q Q

3 7 6 3 1 5 1 5 0

9

9

2

8

9

4

2

9

8

T E L

1 3 9 4 2 2 9 6 5 1 3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

Pin No.

Pin Name

I/O

Description

31

I

–

I

I

I

I

I

I

I

I

I

I

I

End sensor to detect the tape’s terminal (Lead taps section).

If “H” is detected signal in the REW, REV modes, the mechanism stops and ejects the

cassette automatically.

GND

End sensor to detect tape’s terminal (Lead tape section).

If “H” signal is detected in the FF mode, then REW mode will occur automatically.

1. When the tape is transporting. Reel pulses are input.

2. If the tape is transporting and take-up reel pulses are not input during regular time,

the unit stops at STOP point automatically.

3. Distinguishes the tape type, counts the tape remaining and reduces the tape speed at

the end of FF/REW modes.

1. When the tape is transporting, Reel pulses are input.

2. Distinguishes the tape type, counts the tape remaining and reduces the tape speed at

the end of FF/REW modes.

3. If supply reel pulses are not detected, FF/REW mode is not operating normally.

And the unit stops at stop point automatically. (Refer to table of pin 17.)

Input “H” signal from AVCP in super tape PB mode. (option)

Audio “L” signal input for driving level meter on FDP.

Audio “R” signal input for driving level meter on FDP.

Port to detect AFT (+)’s state during tuning. When more than 4V, is detected by AFT

(+) detector.

Detects AFT (–)’s state during tuning. When less than 0.96V, is detected by AFT (–)

detector.

A DC bias level set by VR501 determines the pulse width of PG M.M for H. S/W 30

switching interval.

Input signal to detect Hi-Fi signal. Main signal to perform auto tracking mode.

V.ENV signal is the sub signal.

1. Reference input signal to perform auto tracking mode.

Video envelope (F/F) signal is input through LPF.

2. Perform auto tracking mode by sampling video envelope signal which is input

during a period of head switching and changing servo tracking data to obtain

maximum value.

Note : When the DC level of the envelope is at its maximum, it is considered tracking

properly.

KEY RTN 0

1

2

3

4

5

6

7

8

9

10

11

12

13

TAKE UP

SENSOR

VSS (A/D)

END

SENSOR

TAKE UP REEL

SUPPLY REEL

SQ PB IN

LEVEL METER “L”

LEVEL METER “R”

AFT

PG ADJ

A.ENV

V.ENV

KEY RTN 0

IC DESCRIPTION

IC, HD3977RC36F

Each operating mode

Sec

PLAY, REC

SP=3 EP/LP=6

FF, (REW)

2

CUE, (REV)

1

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

Pin No.

Pin Name

I/O

Description

32

KEY RTN1

1. Input detector port of A/D input key. Samples 256 steps with AVcc in the center and

confirms which key is pressed by the input voltage.

2. Key voltage table.

3. Excluding above item’s key sfter receiving, detecting and amplifying the remocon

data from the remocon receiver (RC5F1), decodes input signals from µ-COM (pin

82), performs its key operation.

A/D Vcc.

1. Initially 5.3 VA is applied to Vcc pin 22 of µ-COM.

This pulses is applied to clear the RAM inside the µ-COM and to reset programs to

0000H in ROM.

2. Reset timing pulse.

Output “H” port to CTL gain control in FF/REW mode.

Input signal for automatic clock setting

1. Output signal to IC502 for control of the loading motor’s direction of rotation.

2. Control table of loading motor’s driving direction.

Switches capstan Vcc to 24 V for high speed rewind.

SYSCON Vcc.

No.

KEY NAME

A/D RANGE

1

SP/EP

0.0V ~ 0.45V

2

CH UP

0.46V ~ 0.96V

3

CH DOWN

0.97V ~ 1.47V

4

STOP/EJECT

1.48V ~ 1.97V

5

REC/ITR

1.99V ~ 2.48V

No.

KEY NAME

A/D RANGE

1

PAUSE

0.0V ~ 0.45V

2

FF

0.46V ~ 0.96V

3

REW

0.97V ~ 1.47V

4

PLAY

1.48V ~ 1.97V

5

POWER

1.99V ~ 2.48V

5.3VA

3.1V

1.5V

RESET

PULSE

RESET Period

Vcc

t

t

Pin 19

Pin20

Rotation of Loading Motor

H

H

Brake Mode.

H

L

Reverse Direction.

L

H

Forward Direction.

I

–

I

O

I

O

O

–

KEY RTN 1

VCC(A/D)

RESET

CTL GAIN ADJ

JUST CLOCK IN

LD (–)

LD (+)

HSR “H” (24V)

Vcc(SYS)

14

15

16

17

18

19

20

21

22www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

Pin No.

Pin Name

I/O

Description

33

Output for the audio head switching 30Hz to the Hi-Fi circuits is made by inputting

DPG, DFG signal through pin 38, 39 for switching Hi-Fi head. Refer to pin 24.

Pulses output for switching video head A and B.

- Produces PG M.M pulses internally by using inputted DPG, DFG pulses to pin 38,

39.

- Produces video head switching 30 Hz pulses by sychronizing at edge point of first

PG. M.M.(PG monostable multivibratior)

- Produces audio head switching 30 Hz pulses by synchronizing at edge point of

second PG.M.M.

- Output pulses (PWM waveform) for controlling capstan motor speed and phase;

control feedback voltage which is inputted to the capstan motor driver IC.

- Output pulses (PWM waveform) for controlling capstan motor stop and drive during

slow mode.

Output pulses (PWM waveform) for controlling drum motor speed and phase; control

feedback voltage which is inputted to the drum motor driver IC.

Provides an output sync signal to prevent the picture from rolling upward or

downward, when the video track is not being scanned in the search mode.

A pulse to control phase of color at Y/C circuit.

Apulse for switching the HEAD SP and EP on the DRUM.

A reference signal for switching video head (SPA, SPB, EPA, EPB) on the drum in

search the mode.

CTL pulse is outputted at recording, CTL pulse is inputted at playback. Functions

which control capstan motor phase at playback, check tape speed, Viss and Real time

counter are performed by using CTL pulse (input/output).

Servo circuit GND in the µ-COM.

Port for gain (Amp) control of CTL pulse during recording and playback.

D.FG pulse input according to rotation of drum motor.

Produces Audio/Video Head S/W 30Hz by using these pulses. And it is used as a

comparison signal for speed control of the drum motor.

One D.PG pulse is generated for each rotation the drum motor and inputted to µ-COM.

When producing Head S/W pulses, D.PG pulse is used as reference point, and it is

used as comparision signal when controlling drum motor phase.

C.FG pulses are generated by the rotating capstan motor and are inputted to µ-COM.

When checking tape speed and controlling. The capstan motor phase, These CFG

pulses are used as comparison signal.

Vcc for servo circuit in the µ-COM.

Vcc for OSD circuit in the µ-COM.

When the OSD display function is activated both video and text are present, when in

the EE or PB modes.

A.H.S/W 30

V.H.S/W 30

CAPSTAN PWM

DRUM PWM

D.V. SYNC.

COLOR ROTARY

HEAD AMP S/W

COMP IN

CTL (+)

CTL (–)

Vss (SERVO)

CTL 1

CTL 2

CTL 3

CTL OUT

D.FG

D.PG

C.FG

Vcc (SERVO)

Vcc (OSD)

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

O

O

O

O

O

O

O

I

I/O

–

I/O

I

I

I

I

I

43

CV IN

I

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

Pin No.

Pin Name

I/O

Description

34

GND.

The video signal is output to the RF modulator and line output jack.

GND.

Horizontal sync is used to lock the OSD.

(Reduce Jitter)

GND.

OSD DOT CLOCK oscillator. (OSD charactor oscillator)

Determining the horizontal position (left or right) of OSD.

Oscillator for OSD Sync. signal.

Generating a blue background.

- Receives composite signal from Y/C circuit.

- Separates V-sync and H-sync in the OSD internal block.

- The sync signal determines the character position of OSD.