飞利浦109B2000液晶显示器维修手册

)

)

)

)

)

)

)

)

)

)

Important Safety Notice . . . . . . . . . . . . . . . . . . . 2

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front View & Back View . . . . . . . . . . . . . . . . . . . 4

OSD Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 5

OSD Lock Function & Service Mode . . . . . . . . . 6

Warning and Notes . . . . . . . . . . . . . . . . . . . . . . . 7

Mechanical Instructions . . . . . . . . . . . . . . . . . . . 8

Safety Test Requirements . . . . . . . . . . . . . . . . . 9

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DDC Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

DDC Instructions. . . . . . . . . . . . . . . . . . . . . . . . . 12~15

Electrical Instructions. . . . . . . . . . . . . . . . . . . . . 16~20

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Control Panel Schematic Diagram & C.B.A. . . 22

Video Panel (A) Schematic Diagram

& Waveforms for Diagram (A). . . . . . . . . . . . 23

Video Panel (A) C.B.A. . . . . . . . . . . . . . . . . . . . . 24

Main Panel (B1, B2, C) C.B.A. . . . . . . . . . . . . . . 25

Deflection (B1) Schematic Diagram

& Waveforms for Diagram (B1). . . . . . . . . . . 26

CPU (B2) Schematic Diagram

& Waveforms for Diagram (B2). . . . . . . . . . . 27

Power Supply (C) Schematic Diagram

& Waveforms for Diagrams (B1) & (C). . . . . 28

Repair Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Exploded View... . . . . . . . . . . . . . . . . . . . . . . . . . 30

Recommended Parts List. . . . . . . . . . . . . . . . . . 31

Spare Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . 32~37

Repair Flow Chart . . . . . . . . . . . . . . . . . . . . . . . 38~45

General Specifications . . . . . . . . . . . . . . . . . . . . 46~70

LightFrame for Windows . . . . . . . . . . . . . . . . . . 71~72

Description

Description

Page

Page

Table of Contents

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

19" Auto scan Colour Monitor

DDC/Power saving /TCO

109B20/00 (PHILIPS)

Horizontal frequencies

30 - 97kHz

Service

Service

Service

Published by BCU Monitors

Printed in Taiwan

Copyright reserved

Subject to modification

July 21 2000

©

GB 3138 106 10109

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

109B2 GSIII CM25

Important Safety Notice

Proper service and repair is important to the safe, reliable operation

of all Philips Company** Equipment. The service procedures

recommended by Philips and described in this service manual are

effective methods of performing service operations. Some of these

service operations require the use of tools specially designed for

the purpose. The special tools should be used when and as

recommended.

It is important to note that this manual contains various CAUTIONS

and NOTICES which should be carefully Read in order to minimize

the risk of personal injury to service personnel. The possibility exists

that improper Service methods may damage the equipment. It also is

important to understand that these CAUTIONS and NOTICES ARE

NOT EXHAUSTIVE. Philips could not possibly know, evaluate and

advise the service trade of all conceivable ways in which service

might be done or of the possible hazardous consequences of each

way. Consequently, Philips has not undertaken any such broad

evaluation. Accordingly, a servicer who uses a service procedure or

tool which is not recommended by Philips must first satisfy himself

thoroughly that Neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

* * Hereafter throughout this manual, Philips Company will be

referred to as Philips.

Critical components having special safety characteristics are

identified with a

by the Ref. No. in the parts list and enclosed

within a broken line* (where several critical components are grouped

in one area) along with the safety symbol

on the schematics or

exploded views.

Use of substitute replacement parts which do not have the same

specified safety characteristics may create shock, fire, or other

hazards.

Under no circumstances should the original design be modified or

altered without written permission from Philips. Philips assumes no

liability, express or implied, arising out of any unauthorized

modification Of design.

Servicer assumes all liability.

WARNING

* Broken Line

FOR PRODUCTS CONTAINING LASER :

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

The use of optical instruments with this

product will increase eye hazard.

DANGER-

CAUTION-

CAUTION-

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR

PART NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

2

109B2 GS3 CM25

� Go to cover page

Forward

Back

109B2 GS3 CM25

3

CRT

Scanning

Video

Size and deflection

: 19" inch / 46 cm; 90 deflection

angle

Dot pitch /Grille pitch

: 0.25 mm

Horizontal pitch

: 0.21 mm

Tube type

: Shadow mask, Real Flat, high

contrast, anti-glare, anti-static,

anti-reflection, light transmission

44%

Phosphor

: P22

Recommended display area

: 14.0" x 10.4" / 355 x 265 mm

Maximum display area

: 14.4" x 10.8" /365 x 274 mm

Horizontal scanning

: 30 - 97 KHz

Vertical scanning

: 50 - 160 Hz

Input impedance

:

- Video

: 75 ohms

- Sync

: 2.2 K ohms

Input signal levels

: 0.7 Vpp

Sync input signal

: Separate sync

Composite sync

Sync polarities

: Positive and negative

�

Technical Specifications

Pin Assignment

Technical Data

1

Red video input

2

Green video input

3

Blue video input

4

Identical output - connected to pin 10

5

6

Red video ground

7

8

Blue video ground

9

No pin

10

Logic ground

11

Identical output - connected to pin 10

12

Serial data line (SDA)

13

H. Sync / H + V

14

V. Sync (VCLK for DDC)

15

Data clock line (SCL)

Pin No.

Assignment

Ground

Green video ground

White Color Temperature

Chromaticity CIE coordinates

:

at 9300 K degrees

: x = 0.283 / y = 0.297

at 6500 K degrees

: x = 0.313 / y = 0.329

at 5500 K degrees

: x = 0.332 / y = 0.347

Physical Characteristics

Dimensions

: 17.3" x 17.5" x 17.6" /

440 x 446 x 448 mm (including base)

440 x 410 x 448 mm (excluding

base)

Weight :

: 21.2 kg

Power supply

: 90- 264 VAC, 50/60Hz

Temperature (operating)

: 0 C to 40 C / 32

Relative humidity

: 5% to 95%

*

Resolution 1280 x 1024, standard size, contrast max., brightness

50%, 9300 K, full white pattern.

** These information are subject to change without notice.

�

�

�

�

�

�

�

�

�

F to 104 F

Temperature (storage)

: -25 C to 65 C / -13 F to 149 F

1

10

6

11

15

5

� Go to cover page

Automatic Power Saving

If you have VESA's DPMS compliance display card or software installed

in your PC, the monitor can automatically reduce its power consumption

when not in use. And if an input from a keyboard, mouse or other input

device is detected, the monitor will automatically "wake up". The

following table shows the power consumption and signaling of this

automatic power saving feature:

Power Management Definition

VESA's

Video

H-sync

V-sync

Power

Power

LED

Mode

Used

Saving

color

ON

Active

Yes

Yes

< 100W

0%

Green

< 10W

90%

Yellow

< 3W

97%

Amber

< 10W

90%

Yellow

Stand-by

Blanked

No

Yes

Suspend

Blanked

Yes

No

OFF

Blanked

No

No

This monitor is ENERGY STAR -compliant. As an ENERGY STAR

Partner, PHILIPS has determined that this product meets the ENERGY

STAR guidelines for energy efficiency.

�

�

�

Forward

Back

4

109B2 GS3 CM25

Go to cover page

Forward

Back

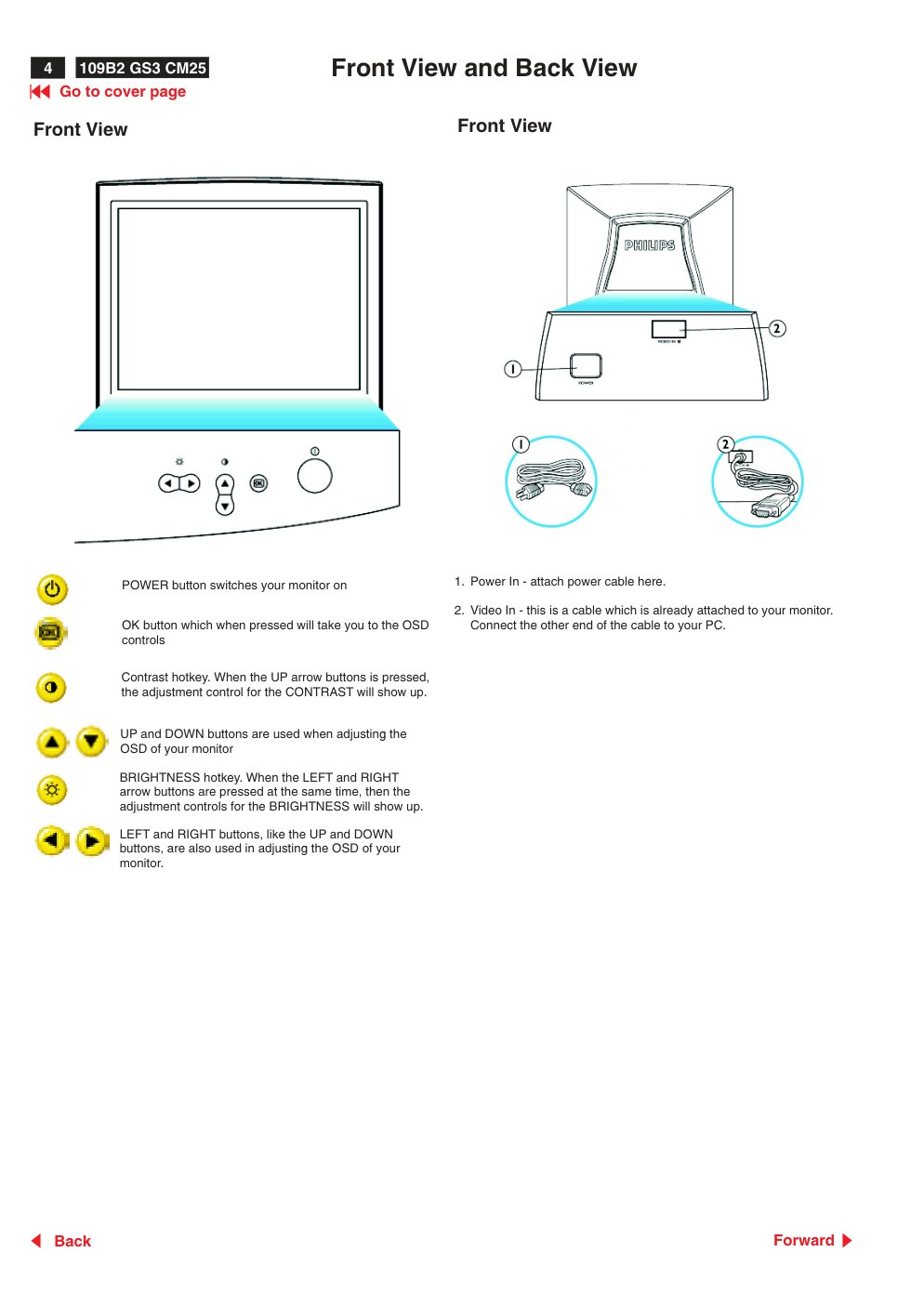

Front View and Back View

Front View

Front View

UP and DOWN buttons are used when adjusting the

OSD of your monitor

LEFT and RIGHT buttons, like the UP and DOWN

buttons, are also used in adjusting the OSD of your

monitor.

BRIGHTNESS hotkey. When the LEFT and RIGHT

arrow buttons are pressed at the same time, then the

adjustment controls for the BRIGHTNESS will show up.

Contrast hotkey. When the UP arrow buttons is pressed,

the adjustment control for the CONTRAST will show up.

OK button which when pressed will take you to the OSD

controls

POWER button switches your monitor on

1. Power In - attach power cable here.

2. Video In - this is a cable which is already attached to your monitor.

Connect the other end of the cable to your PC.

5

109B2 GS3 CM25

Go to cover page

Forward

Back

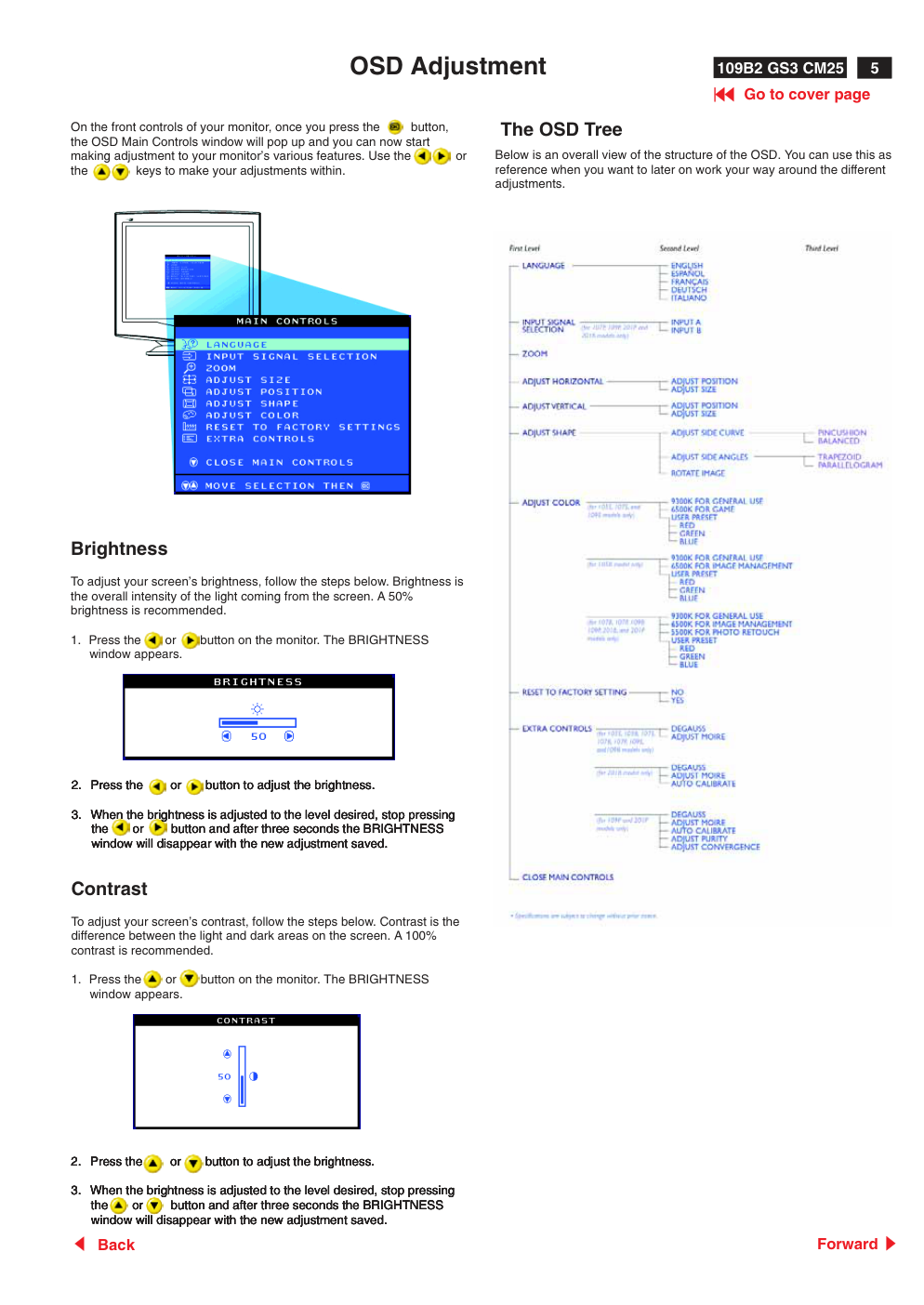

OSD Adjustment

The OSD Tree

On the front controls of your monitor, once you press the

button,

the OSD Main Controls window will pop up and you can now start

making adjustment to your monitor's various features. Use the

or

the

keys to make your adjustments within.

Brightness

1. Press the

or

button on the monitor. The BRIGHTNESS

window appears.

To adjust your screen's brightness, follow the steps below. Brightness is

the overall intensity of the light coming from the screen. A 50%

brightness is recommended.

Contrast

1. Press the

or

button on the monitor. The BRIGHTNESS

window appears.

To adjust your screen's contrast, follow the steps below. Contrast is the

difference between the light and dark areas on the screen. A 100%

contrast is recommended.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

2. Press the

or

button to adjust the brightness.

3. When the brightness is adjusted to the level desired, stop pressing

the

or

button and after three seconds the BRIGHTNESS

window will disappear with the new adjustment saved.

Below is an overall view of the structure of the OSD. You can use this as

reference when you want to later on work your way around the different

adjustments.

6

109B2 GS3 CM25

Go to cover page

Forward

Back

OSD Lock Function & Service Mode

To unlock (enable) OSD function:

- Press OSD button "

" for over 10 seconds again to unlock the

OSD function.

Release it, then OSD comes on the screen as below.

To lock (disable) OSD function:

- Press OSD button "

" for over 15 seconds to lock the OSD function.

Release it, then OSD comes on the screen as below.

ATTENTION

CONTROL MENU IS LOCKED

Disable/Enable all the WARNING SIGNAL

NO SIGNAL INPUT

To enable all the WARNING SIGNAL :

- After disconnect the Interface cable of the monitor, then Monitor is

powered ON.

- If it is successful, the signal "

" comes on the screen

again later.

Access Service mode (burn in mode) :

Access Service Mode & Burn in mode

Firstly, get into Factory Adjustment Mode.

Push LEFT

& RIGHT

buttons at the same time for

over 15 seconds and release them.

The factory message appears at the bottom of the

main OSD menu. (for example : 109B2 V1.52 20000619;

00115 is M.T.B.F. in HOUR unit)

SERVICE MODE

SERIAL NO: TY 123456

HOURS : 00021

FACTORY VER 1.01 990706

109B2 V1.52 20000619

00115

NO SIGNAL INPUT

To disable all the WARNING SIGNAL :

- Disconnect the Interface cable of the monitor (Monitor is ON.).

- Press OSD button "

" for over 15 seconds to disable all the

WARNING SIGNAL. Then release the "OSD" button.

- If it is successful, then the signal "

"disappeared to

enter power saving-off mode.

- Disconnect the Interface cable of the monitor.

- Push LEFT

& RIGHT

buttons at the same time, then power

ON.

- If it is successful, the signal "

"

comes on the screen later.

(Background is white.).

- Reconnect the interface cable to PC, then the "burn in MODE"

disappear.

Exit "burn in MODE" :

109B2 GS3 CM25

7

Warning and Notes

Fig.1

V

Warnings

1.

Safety regulations require that the unit should be returned

in its original condition and that components identical to

the original components are used. The safety components

are indicated by the symbol

.

2.

In order to prevent damage to ICs and transistors, all

high-voltage flash-overs must be avoided. In order to

prevent damage to the picture tube, the method shown

in Fig. 1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position DC-V).

Discharge until the meter reading is 0 V (after approximately

30 seconds).

3.

ESD

All ICs and many other semiconductors are sensitive to

electrostatic discharges (ESD). Careless handling during

repair can drastically shorten their life. Make sure that

during repair you are connected by a pulse band with

resistance to the same potential as the ground of the unit.

Keep components and tools also at this same potential.

4.

When repairing a unit, always connect it to the AC Power

voltage via an isolating transformer.

5.

Be careful when taking measurements in the high-voltage

section and on the picture tube panel.

6.

It is recommended that saferty goggles be worn when

replacing the picture tube.

7.

When making adjustments,use plastic rather than metal tools.

This will prevent any short-circuit or the danger of a

circuit becoming unstable.

8.

Never replace modules or other components while the

unit is switched on.

9.

Together with the defleciton unit, the picture tube is used

as an integrated unit. Adjustment of this unit during repair

is not recommended.

10. After repair, the wiring should be fastened in place with

the cable clamps.

11. All units that are returned for service or repair must pass

the original manufactures safety tests.

Notes

1.

The direct voltages and waveforms are average voltages.

They have been measured using the Service test software

and under the following conditions :

-

Mode : 1024 * 768 (56.5kHz / 70Hz)

-

Signal pattern : grey scale

-

Adjust brightness and contrast control for the

mechanical mid-position (click position)

2.

The picture tube panel has printed spark gaps.

Each spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

3.

The semiconductors indicated in the circuit diagram(s)

and in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

� Go to cover page

Forward

Back

Mechanical Instructions

8

109B2 GS3 CM25

Fig. 5

Fig. 4

Fig. 3

Fig. 6

Fig. 8

Fig. 2

Fig. 7

screw

0. Location of the panel

1. General

0.1 Main panel (1155)

0.2 Video panel (1157)

To be able to perform measurements and repairs on the "circuit

boards", the monitor should be placed in Service Position (fig. 1) first:

There are 2 screws in the lid [1 screw are at the right side of the

monitor, the other 1 screw are at the left side of the monitor],to fix the

front cabinet and back cover of the monitor.

Step 1: To open the lid at the right-upper side and 1

right-

downer side of the monitor.(FIG.3)

Step 2: To open the lid at the left-upper side and

left-

downer side of the monitor.(FIG.4)

Step 3: To remove the backcover, you can see FIG.5

Step 4: To remove the16 screws on the metal shield, and remove the

metal shield, you can see FIG.6.

- After remove the back cover & metal shield, you can see the inside

of the monitor as Fig. 6.

- To remove 5 screws for service position as Fig. 6 to Fig. 8.

- Including remove bottom plate screw, then slide out chassis board

and disconnect metal shield.

- After remove the metal frame (Fig. 5), to remove the metal shield on

rear side of Video panel for measurement.

After remove the metal frame.

- To cut out cable tie and disconnect "video panel"

- To disconnect EHT cable

- To disconnect ground wire(1703) of video board.

- To disconnect M1802(6pin) to control panel.

- To disconnect M1401(4pin) yoke connector.

- To disconnect M1603(2pin) degaussing coil

- To slide out Main panel as Fig. 1.

To get service position as Fig. 1 through Fig. 2 to Fig. 8.

After the service position was obtained, all the panel's copper track

side could be accessed.

How to remove the back cover of monitor :

screw in

1screw in

Chassis :

Video panel :

Main panel :

Service position :

2. Repair instructions

Service Position

Fig. 1

1157

lids

screws

1155

Go to cover page

Forward

Back

9

109B2 GS3 CM25

Go to cover page

Forward

Back

Safety Test Requirements

2.2.1 The test with AC voltage is only for production purpose,

Service center shall use DC voltage.

2.2.2 The minimum test duration for Quality Control Inspector

must be 1 minute. No breakdown during the test.

2.2.3 The test voltage must be maintained within the specified

voltage + 5%.

2.2.4 The grounding blade or pin of mains plug must be

conducted with accessible metal parts.

All units that are returned for service or repair must pass the original

manufactures safety tests. Safety testing requires both

and

testing.

Hi-pot

Ground Continuity

HI-POT TEST INSTRUCTION

1. Application requirements

2. Test method

1.1

All mains operated products must pass the Hi-Pot test as

described in this instruction.

1.2

This test must be performed again after the covers have

been refitted following the repair, inspection or modification

of the product.

2.1

Connecting conditions

2.1.1 The test specified must be applied between the parallel-

blade plug of the mainscord and all accessible metal

parts of the product.

2.1.2 Before carrying out the test, reliable conductive

connections must be ensured and thereafter be

maintained throughout the test period.

2.1.3 The mains switch(es) must be in the "ON" position.

2.2

Test Requirements

All products should be HiPot and Ground Continuity tested as follows:

Condition

HiPot Test for

HiPot Test for

Ground Continuity

products where

products where

Test requirement

the mains input

the mains input is

range is Full

110V AC(USA

range(or 220V

type)

AC)

Test

2820VDC

1700VDC

Test current:

voltage

(2000VAC)

(1200VAC)

25A,AC

Test time:

Test time

3 seconds

1 second

3 seconds(min.)

(min.)

Resistance

required:

Trip

set at 100 uA

5 mA

<=0.09+R ohm,

current

for Max.

R is the

(Tester)

limitation; set

resistance of

at 0.1 uA for

the mains cord.

Min. limitation

Ramp

set at 2

time

seconds

(Tester)

3. Equipments and Connection

4. Recording

3.1

Equipments

For example :

- ChenHwa 9032 PROGRAMMABLE AUTO SAFETY

TESTER

- ChenHwa 510B Digital Grounding Continuity Tester

- ChenHwa 901 (AC Hi-pot test), 902 (AC, DC Hi-pot test)

Withstanding Tester

3.2

Connection

Hipot and Ground Continuity testing records have to be kept for a period

of 10 years.

* Turn on the power switch of monitor before Hipot and

Ground Continuity testing.

Connect the "video cable"

or "grounding screw"

to the CLIP on your tester.

Video cable

(Rear view of monitor)

Connect the power cord

to the monitor.

Grounding screw

Power outlet

(ChenHwa 9032 tester)

Clip

Clip

10

109B2 GS3 CM25

Go to cover page

Forward

Back

Wiring Diagram

8801

8601

10

1113

3

1401

1603

1

1713

9

1714

10

1301

13

1

TO YOKE

1712

RED

GRAY

WHITE

TO HVG

RED

GRAY

WHITE

88911

1605

1

1

2

3

DEGAUSSING COIL

EARTH WIRE

CONTROL PCB ASSY

MAIN PCB ASSY

YOKE

VIDEO PCB ASSY

1802

TO POSITION 1714 OF VIDEO PCB

1713

TO INSERT CRT NECK

(DETAIL POSITION REFER

SHEET 132 PHOTO)

TO INSERT CRT NECK

(DETAIL POSITION REFER

SHEET 132 PHOTO )

TO PLUG IN BOTTOM PLATE - B

TO PLUG IN BOTTOM PLATE - A

TO PLUG IN BOTTOM PLATE - C

BOTTOM PLATE

A

B

C

11

109B2 GS3 CM25

Go to cover page

Forward

Back

DDC Data

**********************************************************************

EDID log file for HTC tube

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name

: PHL

ID Product Code

: E007 (HEX.)

ID Serial Number

: 12345 (DEC.)

Week of Manufacture

: 28

Year of Manufacture

: 2000

EDID Version, Revision

Version

: 1

Revision

: 2

Basic Display Parameters/Features

Video Input Definition

: Analog Video Input

0.700V/0.000V (0.70Vpp)

without Blank-to-Black Setup

Separate Sync

without Composite Sync

without Sync on Green

no Serration required

Maximum H Image Size

: 36

Maximum V Image Size

: 27

Display Transfer Characteristic: 2.76

(gamma)

Feature Support (DPMS)

: Standby

Suspend

Active Off

Display Type

: RGB color display

Color Characteristics

Red

X coordinate

: 0.625

Red

Y coordinate

: 0.34

Green X coordinate

: 0.285

Green Y coordinate

: 0.605

Blue X coordinate

: 0.15

Blue Y coordinate

: 0.065

White X coordinate

: 0.283

White Y coordinate

: 0.297

Established Timings

Established Timings I

: 720 x 400 @70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II

: 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings

: 1152 x 870 @75Hz (Apple,Mac II)

Standard Timing Identification #1

Horizontal active pixels

: 640

Aspect Ratio

: 4:3

Refresh Rate

: 85

Standard Timing Identification #2

Horizontal active pixels

: 800

Aspect Ratio

: 4:3

Refresh Rate

: 85

Standard Timing Identification #3

Horizontal active pixels

: 1024

Aspect Ratio

: 4:3

Refresh Rate

: 85

Standard Timing Identification #4

Horizontal active pixels

: 1280

Aspect Ratio

: 5:4

Refresh Rate

: 85

Standard Timing Identification #5

Horizontal active pixels

: 1600

Aspect Ratio

: 4:3

Refresh Rate

: 75

Standard Timing Identification #6

Horizontal active pixels

: 1920

Aspect Ratio

: 4:3

Refresh Rate

: 60

Detailed Timing #1

Pixel Clock (Mhz)

: 202.5

H Active (pixels)

: 1600

H Blanking (pixels)

: 560

V Active (lines)

: 1200

V Blanking (lines)

: 50

H Sync Offset (F Porch) (pixels)

: 64

H Sync Pulse Width (pixels)

: 192

V Sync Offset (F Porch) (lines)

: 1

V Sync Pulse Width (lines)

: 3

H Image Size (mm)

: 360

V Image Size (mm)

: 270

H Border (pixels)

: 0

V Border (lines)

: 0

Flags

: Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number

: TY 123456

Monitor Descriptor #3

Monitor Name

: PHILIPS 109B2

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz

: 50

Max. Vt rate Hz

: 160

Min. Horiz. rate kHz

: 30

Max. Horiz. rate kHz

: 97

Max. Supported Pixel

: Not specified

Extension Flag

: 0

Check sum

: A5 (HEX.)

**********************************************************************

EDID data (128 bytes)

**********************************************************************

0: 00

1: ff

2: ff

3: ff

4: ff

5: ff

6: ff

7: 00

8: 41

9: 0c

10: 07

11: e0

12: 39

13: 30

14: 00

15: 00

16: 1c

17: 0a

18: 01

19: 02

20: 68

21: 24

22: 1b

23: b0

24: e8

25: 00

26: b8

27: a0

28: 57

29: 49

30: 9b

31: 26

32: 10

33: 48

34: 4c

35: ad

36: ef

37: 80

38: 31

39: 59

40: 45

41: 59

42: 61

43: 59

44: 81

45: 99

46: a9

47: 4f

48: d1

49: 40

50: 01

51: 01

52: 01

53: 01

54: 1a

55: 4f

56: 40

57: 30

58: 62

59: b0

60: 32

61: 40

62: 40

63: c0

64: 13

65: 00

66: 68

67: 0e

68: 11

69: 00

70: 00

71: 1e

72: 00

73: 00

74: 00

75: ff

76: 00

77: 20

78: 54

79: 59

80: 20

81: 20

82: 31

83: 32

84: 33

85: 34

86: 35

87: 36

88: 0a

89: 20

90: 00

91: 00

92: 00

93: fc

94: 00

95: 50

96: 48

97: 49

98: 4c

99: 49

100: 50

101: 53 102: 20 103: 31

104: 30 105: 39 106: 42 107: 32 108: 00

109: 00 110: 00 111: fd

112: 00 113: 32 114: a0 115: 1e

116: 61

117: ff

118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20

125: 20 126: 00 127: a5

12

109B2 GS3 CM25

Go to cover page

Forward

Back

DDC Instructions

1. General

3. Pin assignment

Fig. 2 Alignment Kits

To Monitor

DC 8V~12V

Video Card

Video Card

To Printer

Power indicator

A. 15-pin D-Sub Connector

DDC Data Re-programming

In case the main EEPROM with

which store all factory

settings were replaced because a defect,repaired monitor’ the serial

numbers have to be re-programmed.

It is advised to re-soldered the main EEPROM

from

the old board onto the new board if circuit board have been replaced, in

this case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

DDC EDID structure

For the monitor

: Standard Version

3.0

Structure Version

1.2

1.

An i486 (or above) personal computer or compatible.

2.

Microsoft operation system Windows 95/98.

4.

Software DDC Alignment kits (4822 310 11184) shown as Fig. 2.

The kit contents: a. Alignment box x1

b. Printer cable

x1

c. D-Sub cable

x1

Note: The EDID301.EXE (Release Version 1.54, 2000.04.25)is a

windows-based program, which cannot be run in MS-DOS.

Software DDC

with Software DDC

3.

EDID301.EXE program (3138 106 10103) shown as Fig. 1

2. System and equipment requirements

Diskette with EDID301.EXE

EDID301.EXE

Figure 1

Ver:1.54

The 15-pin D-sub connector (male) of the signal cable

on the 3rd row for DDC feature :

1

Red video input

2

Green video input

3

Blue video input

4

Identical output - connected to pin 10

5

6

Red video ground

7

8

Blue video ground

9

No pin

10

Logic ground

11

Identical output - connected to pin 10

12

Serial data line (SDA)

13

H. Sync / H + V

14

V. Sync (VCLK for DDC)

15

Data clock line (SCL)

Pin No.

Assignment

Ground

Green video ground

1

10

6

11

15

5

13

109B2 GS3 CM25

Go to cover page

Forward

Back

DDC Instructions (Continued)

4. Configuration and procedure

Following descirptions are the connection and procedure for Software

DDC, the main EEPROM can be re-programmed along with Software

DDC by enabling “factory memory data write” function on the DDC

program (EDID301.EXE).

5. DDC re-programming instructions

Start on DDC program

Start Microsoft Windows.

1. Insert the disk containing EDID301.EXE program into floppy disk

drive.

2. Click

, choose Run at start menu of Windows 95/98.

4. At the submenu, type the letter of your computer's floppy disk drive

followed by :EDID301 (for example, A:\EDID301, as shown in Fig. 5).

Fig. 5

Initialize alignment box

In order to avoid that monitor entering power saving mode due to sync

will cut off by alignment box, it is necessary to initialize alignment box

before running programming software (EDID301.EXE). Following steps

show you the procedures and connection.

Step 1: Supply 8~12V DC power source to the Alignment box by

plugging a DC power cord or using batteries.

Step 2: Connecting printer cable and video cable of monitor as Fig. A

Step 3: Run the EDID301.EXE program until the main menu appears.

This is for initialize alignment box.

~~

PC

To video card

To printer port (LTP1)

DC Power

8~12 V

Fig. 3

Printer

Port

Re-programming Software DDC

Step 1: After initialize alignment box, connecting all cables and box as

Fig. 3

Step 2: Follow the steps on DDC re-programming instructions to staring

re-programming.

To

Monitor

To PC

Rear view of the monitor

Video cable

~~

PC

To printer port (LTP1)

DC Power

8~12 V

Fig. A

Printer

Port

To video card

To

Monitor

To PC

Video cable

Rear view of the monitor

A:\edid301�

14

109B2 GS3 CM25

Go to cover page

Forward

Back

DDC Instructions (Continued)

Loading DDC data from monitor

1.

Click

icon on the tools bar to bring up the Configuration Setup

windows as Fig.7

2.

Select the DDC2B as the communication channel.

3.

Enable Factory memory data write function and fill in page address

“FA” to the block.

4..

Click

button to confirm your selection.

Note: The Factory memory data write function will allow EDID301 to

rewrite the serial numbers of Software DDC data in main

EEPROM.

5. Click

button. The main menu appears (as shown on Fig. 6).

Fig. 6

Note:

If the connection is improper, you will see the following error

message before entering the main menu. Meanwhile, the

(read EDID) function will be disable. At this time, please make

sure all cables are connected correctly and fixedly, and the

procedure has been performed properly.

4.

Click

icon to read DDC EDID data from monitor. The EDID

codes will display on screen as following. (The EDID codes are

dependent on the model.)

Command bar

Tools bar

Status bar

Fig. 7

Modify DDC data (Serial No.)

1.

Click

icon on the tool bar.

2.

Click

till the Step 7 of 9 window appears.

3.

Type the new Serial No. (for example, TY 123456).

4.

Click

till the last step window appears, then click

to

exit the Step window.

Note:

During the loading, EDID301 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen (Fig. 8). Please confirm

following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. Software DDC Data that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

5. Software DDC only is disable.

Fig. 8

1

F0

15

109B2 GS3 CM25

Go to cover page

Forward

Back

DDC Instructions (Continued)

Load DDC data from file

1.

Click

from the tools bar.

2.

Select the file you want to open.

3.

Click .

Button.

Exit DDC program

1.

Click file command on the command bar then select Exit.

Write DDC data to monitor

1.

Click

icon from the tools bar to starting rewrite DDC data.

2.

Click

for confirmation.

Save DDC data as a file

Sometimes, you maybe need to save DDC data as a text file for using

on other DDC chip. To save DDC data, follow the steps below:

1.

Click

icon on the tools bar and type a file name you like. The

file format is ddc type which can be open by Microsoft WordPad.

2.

Click

button.

Definition of Serial Number

T Y 0 0 0 0 2 8 0 0 0 0 0 1

Serial Number (U.S.A: 8 digit)

Week

Year

TY Code

TY----Chungli

CX----Dong Guan

HD----Hungary

BZ----Suzhou

(Others regions: 6 digit)

4.

Now you can re-programming DDC data which you just loaded

from a file, please be confirmed that model and serial number are

correct and match with the monitor you are trying to re-write.

1

1

16

109B2 GS3 CM25

Go to cover page

Forward

Back

Electrical Instructions

0. General

1. B+ supply voltage (3165) 79Vdc

2. High-voltage EHT (3587)

When carry-out the electrical settings in many cases a video

signal must be applied to the monitor. A computer with :

- ATI GPT-1600 (4822 397 10065), Mach 64 (up to 107kHz)

are used as the video signal source. The signal patterns

are selected from the "service test software" package, see

user guide 4822 727 21046 (GPT-1600).

The measurements for AC waveform and DC figure is based

on 640 x 480 31.5 kHz/60 Hz resolution mode with test

pattern "gray scale".

Power input: 110V AC

- Apply a video signal in the 1024 x 768 with 68.7 kHz/85Hz

mode.

- Select the "cross-hatch" pattern.

- Set the brightness control and the contrast control to the

minimum

position.

- Pre-set trimming potentiometer R3165(B+) and

R3587(EHT) in mid-position.

- Set Vg2 (screen) to fully Counter-clockwise (zero

beamcurrent).

- Connect a dc voltmeter between the joint of C2152 and

ground (common ground).

- Set the B+ trimming potentiometer 3165 so that the reading

on the dc voltmeter is 190.0 V +/- 0.5 Vdc.

- Apply a video signal in the 1024 x 768 with 68.7 kHz/85Hz

mode.

- Select the "cross-hatch" pattern.

- Set the brightness control and the contrast control to the

minimum position.

0.1 This monitor has 35 factory-preset modes as below:

z

0.2 With normal VGA card:

If not using the ATI card during repair or alignment, The

service engineer also can use this service test software

adapting with normal standard VGA adaptor and using

standard VGA mode 640 x 480, 31.5 kHz/60 Hz (only) as

signal source.

0.3 AC/DC Measurement:

640 x 350 37.9 kHz/85 Hz

1152 x 870 68.7 kHz/75 Hz

640 x 400 31.5 kHz/70 Hz

1152 x 900 71.8 kHz/76 Hz

640 x 480 31.5 kHz/60 Hz

1280 x 960 60.0 kHz/60 Hz

640 x 480 37.9 kHz/72 Hz

1280 x 960 85.9 kHz/85 Hz

640 x 480 37.5 kHz/75 Hz

1280 x 1024 63.9 kHz/60Hz

640 x 480 43.3 kHz/85 Hz

1280 x 1024 79.9 kHz/75 Hz

640 x 480 50.6 kHz/100 Hz

1280 x 1024 91.1 kHz/85 Hz

0 x 400 31.5 kHz/70 Hz

1600 x 1200 75.0 kHz/60 Hz

720 x 400 37.9 kHz/85 Hz

1600 x 1200 81.3 kHz/65 Hz

800 x 600 37.9 kHz/60 Hz

1600 x 1200 87.5 kHz/70 Hz

800 x 600 48.1 kHz/72 Hz

1600 x 1200 93.8 kHz/75 Hz

800 x 600 46.9 kHz/75 Hz

1792 x 1344 83.6 kHz/60 Hz

800 x 600 53.7 kHz/85 Hz

1856 x 1392 86.3 kHz/60 Hz

800 x 600 63.9 kHz/100 Hz

1920 x 1440 90.0 kHz/60 H

832 x 624 49.7 kHz/75 Hz

1024 x 768 48.4 kHz/60 Hz

1024 x 768 56.5 kHz/70 Hz

1024 x 768 60.0 kHz/75 Hz

1024 x 768 68.7 kHz/85 Hz

1152 x 864 67.5 kHz/75 Hz

1152 x 864 77.1 kHz/85 Hz

72

- Connect a "high-voltage voltmeter" between the high-

voltage connection of the picture tube and earth.

- Turn on the power.

- Set the EHT trimming potentiometer R3587 so that the

"high-

voltage voltmeter" reads 26.5 KV +/- 0.5 KV .

- Turn off the power.

- Remove the "high-voltage voltmeter" from the picture tube.

- Turn on the power again.

3. Monitor the following auxiliary voltages.

SOURCE ACROSS C2152 + 190.0V +/- 1.0VDC.

SOURCE ACROSS C2154 +

79.0V +/- 1.0VDC.

SOURCE ACROSS C2156

-

6.3V +/- 0.3VDC.

SOURCE ACROSS C2160 +

13.5V +/- 0.5VDC.

SOURCE ACROSS C2157 -

13.5V +/- 0.5VDC.

4. General conditions for alignment

4.1 During all alignments, supply a distortion free AC mains

voltage to set via an isolating transformer with low internal

impedance.

4.2 Align in pre-warmed condition, at least 30 minutes warm-

up with nominal picture brightness.

4.3 Purity, geometry and subsequent alignments should be

carried out in magnetic cage with correct magnetic field.

Northern hemisphere : H=0, V=430+/-50 mG, Z=0

Southern hemisphere : H=0, V=-520+/-50 mG, Z=0

4.4 All voltages are to be measured or applied with respect to

ground.

Note: Do not use heatsink as ground.

4.5 Adjust function controls "

" to center position except

for contrast control which should be set to MAX.

5. To access factory mode:

- Turn off monitor (don't turn off PC)

- Press "

" and "

" simultaneously on the front

control panel, then press "

",wait till the OSD menu

with characters " factory mode (below OSD menu)" come

on the screen of monitor.

109B2 V1.52 20000619

00115

- If OSD menu disappears on the screen of monitor, press

"

" again (anytime), then the OSD menu comes on the

screen again.

- using "

" : to select OSD menu.

: to increase or decrease the setting.

- Using "

" to confirm the selection.

17

109B2 GS3 CM25

Electrical Instructions (Continued)

.

7.1 Connect the video input, set brightness control at 50%

and contrast at minimum position (OSD), Vg2 at Minimum

(counter clockwise, and ABL (OSD) at 50% position.

Slowly increase Vg2 voltage until light output is at

0.1 Ft-L +/- 0.01Ft-L (Y=0.1 Ft-L, on the screen of CA-

100).

7.2 (The screen of monitor is dark now)

: Press "

" to show the OSD menu as shown in Fig.

2.1.

: Select the character "FACTORY MODE" to access the

R/G/B adjustment as shown in Fig. 2.2 and Fig. 2.3.

: Adjust the cutoff of R/G/B to get 9300K

(x=0.283 +/- 0.015, y=0.297 +/- 0.015), and brightness

output at 0.07 +/- 0.01 Ft-L (Y=0.07Ft-L).

7.3 : Press "

" to set contrast at maximum (100%).

: Adjust gain of R/G/B to get 9300K

(x=0.283 +/- 0.015, y=0.297 +/-0.015, don't care about

the Y value)

7.4 Apply a small white square 10 x 10 cm pattern, brightness

set to center (50%), and contrast at maximum (100%),

adjust Sub-contrast control (OSD) to reach 44 +/- 1 Ft-L.

7.5 Apply full white pattern at 9300K, adjust ABL (OSD) to

reach 30+/- 1 Ft-L (contrast at maximum 100%,

brightness at center 50%).

LF

: LightFrame

BIAS R G B : R(red) G(green) B(blue) cutoff

GAIN R G B : R(red) G(green) B(blue) gain

V FOCUS : Vertical Focus

H FOCUS : Horizontal Focus

VLIN BAL : Vertical Linearity Balance

USER

: Horizontal size range

RASTER H: Horizontal raster Shift

RASTER V: Vertical raster Shift

HLIN

: Horizontal Linearity

V LIN

: Vertical Linearity

SUB

: Zoom Control range

SUB

: Sub Contrast

V OFFSET : Vertical offset

V GAIN

: Vertical Gain

ABL

: Auto Beam Limit

T CORNER: Corner Correctionof TOP

B CORNER: Corner Correctionof BOTTOM

6 To leave factory mode

* After alignment of factory mode, turn off monitor (if you do

not turn off monitor, the OSD menu is always at the factory

mode), then turn on monitor again (at this moment, the

OSD menu goes back to user mode).

TIMER

Set OSD display time.

5500 K

R cutoff = 40%, R gain = 55% (I C)

G cutoff = 40%, G gain = 55% (I C)

B cutoff = 40%,

B gain = 55% (I C)

2

2

2

2

2

2

2

2

2

�

7. Alignment of Vg2 cut-off point, white tracking (OSD

control)

Equipment : 1. Video Test Generator-801GC (Quantum

Data)

2. Color-analyzer (Minolta CA-100)

VG2 [(screen), at the bottom of the L.O.T.].

* Apply a video signal in the 1024 x 768 with 68.7 kHz/85 Hz

mode,

select the "full white pattern" (sizes 355 x 265 mm).

* Use color-analyzer (Minolta CA-100) to adjust cutoff and

white uniformity.

OSD R/G/B cut-off and R/G/B gain can be accessed, with

initial data:

9300 K

R cutoff = 40%, R gain = 65% (I C)

G cutoff = 40%, G gain = 65% (I C)

B cutoff = 40%,

B gain = 65% (I C)

6500 K

R cutoff = 40%, R gain = 55% (I C)

G cutoff = 40%, G gain = 55% (I C)

B cutoff = 40%,

B gain = 55% (I C)

Brightness = 50%, Sub-Contrast = 85%, ABL = 70% (I C)

Step 1: To select the character "FACTORY MODE" as shown

in Fig. 2.1, press "

" to access the OSD menu for

R/G/B gain & cutoff as shown in Fig. 2.2.

Step 2: Press "

" for function selection as shown in Fig

2.3.

Step 3: Use "

" to increase or decrease the value as

shown in Fig. 2.3.

�

�

2

After pressing "

" ,then Press "

"

2

Fig.2.1

Fig. 2.2

Fig. 2.3

9300 BIAS

R G B

GAIN R G B

6500 BIAS

R G B

GAIN R G B

5500 BIAS

R G B

GAIN R G B

FOCUS(H V) VLINBAL USER

RASTER(H V) LIN ( H V ) SUB

V(OFFSET GAIN)

SUB

CORNER(T B) ABL

LF(BRIGH SHARP)

LF(BRIGH SHARP)

EXIT

135

9300 BIAS

R G B

GAIN R G B

6500 BIAS

R G B

GAIN R G B

5500 BIAS

R G B

GAIN R G B

FOCUS(H V) VLINBAL USER

RASTER(H V) LIN ( H V ) SUB

V(OFFSET GAIN)

SUB

CORNER(T B) ABL

EXIT

135

109B2 V1.52 20000619

00115

Go to cover page

Forward

Back

18

109B2 GS3 CM25

Electrical Instructions (Continued)

9. Focus adjustment

10. Loading DDC code

: Apply a video signal in the 1600 x 1200 with 93.8 kHz/75

Hz mode

: Select " @

" pattern.

: Set the brightness at center (50%) and the contrast to 25

FL.

: Adjust focus potentiometers (top of L.O.T.) Focus 1 for

horizontal focus and Focus 2 for vertical focus so that the

picture at 2/3 of the diagonal lines (from center to four

corners) of the displayed screen is as sharp as possible.

The DDC HEX data should be written

into the DDC IC by EEPROM writer or EDID301.EXE

program and Software DDC Alignment Kit.

7.6 : Select the 6500K colour temperature as shown in Fig.

2.2.

: Adjust the R/G/B cutoff and R/G/B gain as shown in

procedure 7.2~7.3 to get

R/G/B cutoff

x= 0.313 +/- 0.015

y= 0.329 +/- 0.015

R/G/B gain

x= 0.313 +/- 0.015

y= 0.329 +/- 0.015

Y= 38 +/- 1 Ft-L

7.7 : Select the 5500K colour temperature as shown in Fig.

2.2.

: Adjust the R/G/B cutoff and R/G/B gain as shown in

procedure 7.2~7.3 to get

R/G/B cutoff

x= 0.332 +/- 0.015

y= 0.347 +/- 0.015

R/G/B gain

x= 0.332 +/- 0.015

y= 0.347 +/- 0.015

Y= 33 +/- 1 Ft-L

- Apply a video signal with cross-hatch pattern.

- Apply a video signal in the 1024 x 768 with 68.7 kHz/85 Hz

mode.

- Set brightness and contrast controls to their center positions

(OSD control).

8. Picture geometry setting (factory pre-set modes)

8.1 Horizontal geometry (OSD control)

- Adjust the H-width to 355 mm

- Adjust the H-phase to center position.

8.2 Vertical geometry (OSD control)

- Adjust vertical size to 265 mm

- Adjust V-phase to center position.

8.3 Trapezoid distortion (OSD control)

- Adjust the trapezoid to get optimal vertical lines.

8.4 Pincushion (OSD control)

- Adjust the pincushion to get optimal vertical line.

8.5 Parallelogram (OSD control)

- Adjust parallelogram so that vertical lines are vertical or

symmetrically about the center vertical axis.

8.6 Unbalance-pin (OSD control)

- Adjust the unbalance-pin so that that vertical border lines

are aligned symmetrically.

8.7 Rotation (OSD control)

- Adjust picture so that vertical tilt is less than +/- 0.5mm.

8.8 Top/Bottom corner(control)

- Adjust the top/bottom corner control to get optimum corner

geometry.

8.9 Store the preset results by selecting the "exit" (OSD

control).

8.10 Repeat the procedure 8.1 to 8.9 until all the preset

timings have been adjusted completely

Go to cover page

Forward

Back

19

109B2 GS3 CM25

Go to cover page

Forward

Back

Electrical Instructions (Continued)

CHARACTER

FOR FOCUS

IMAGE GEOMETRY

355 mm

265 mm

A, B < 2.0 mm

C, D < 2.0 mm

A

B

C

D

Item Resolution

Freq. V x H

Pixel rate(Mhz)

Remark

1

640x350

85(37.861k)

31.500

VESA

2

640x350

70(31.469k)

25.175

VGA

3

640x480

60(31.469k)

25.175

VGA

4

72.8(37.861k)

31.500

VESA

5

75(37.500k)

31.500

VESA

6

85(43.269k)

36.000

VESA

7

100.1(50.60k)

40.500

SNI

8

720x400

70(31.469k)

28.321

VGA

9

85(37.927k)

35.500

VESA

10

800x600

60.3(37.879k)

40.000

VESA

11

72.12(48.077k)

50.000

VESA

12

75(46.875k)

49.500

VESA

@13

85(53.674k)

56.250

VESA

14

100.1(63.90k)

67.500

SNI

15

832x624

74.6(49.725k)

57.280

MAC

16

1024x768

60(48.363k)

65.000

VESA

17

70(56.476k)

75.000

VESA

@18

75(60.000k)

78.750

VESA

@19

84.997(68.677k)

94.500

VESA

20

1152x864

75(67.500k)

108.000

VESA

21

85(77.100k)

121.500

VESA/P

22

1152x870

75(68.681k)

100.000

MAC

23

1152x900

76(71.800k)

108.000

SUN

24

1280x960

60(60.000k)

108.000

VESA

25

85(85.938k)

148.500

VESA

26

1280x1024

60(63.981k)

108.000

VESA

@27

75(79.976k)

135.000

VESA

@28

85(91.146k)

157.500

VESA

29

1600x1200

60(75.000k)

162.000

VESA

30

65(81.250k)

175.500

VESA

31

70(87.500k)

189.000

VESA

@32

75(93.750k)

202.500

VESA

33

1792x1344

60(83.640k)

204.750

VESA/P

34

1856x1392

60(86.333k)

218.250

VESA/P

35

1920x1440

60(90.000k)

234.000

VESA/P

20

109B2 GS3 CM25

1.

Purity adjustment

2.

Static convergence

- Make sure the monitor is not exposed to any

external magnetic field.

- Produce a full red pattern on the screen, adjust the

purity magnet rings on the PCM assy (on CRT) to

obtain a complete field of the color red. This is done

by moving the two tabs (2-pole) in such a manner

that they advance in an opposite direction but at

the same time to obtain the same angle between

the two tabs, which should be approximately 180

degree.

- Check by full green pattern and full blue pattern

again to observe their respective color purity.

Introduction

Slight deviation in the static convergence can be

corrected by using two permanent pairs of magnets

which are fitted around the neck of the CRT. These

are the 4-pole magnet and the 6-pole magnet.

The 4-pole magnet move the outermost electron

beams (R and B) parallel in the opposite direction

from the other. The 6-pole magnet moves the

outermost electron beam (R, B and G) parallel in the

opposite direction from the other.

The magnetic field of the above magnets do not affect

the center of the CRT neck.

Setting

- Before the static convergence setting can be made,

the monitor must be switched on for 30 minutes.

- The focus setting must be made correctly.

- Signal: 640 * 480, 31.5 kHz/60 Hz mode.

- Set the tabs of the 4-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R and B electron beams.

- Set the tabs of the 6-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R, B, and G electron beams.

- First set the 4-pole magnet optimally.

- Then set the 6-pole magnet optimally.

- If the convergence is not now optimal, then adjust to

the optimal setting with the 4-pole magnet and then with

the 6- Pole magnet again.

- Set the tabs of the 6-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R, B, and G electron beams.

- First set the 4-pole magnet optimally.

- Then set the 6-pole magnet optimally.

- If the convergence is not now optimal, then adjust to

the optimal setting with the 4-pole magnet and then

with the 6- pole magnet again.

2-pole purity magnet

6-pole convergence magnet

4-pole convergence magnet

Deflection Yoke

4-pole

Beam motion producced by the

4-pole convergence magnet

S

S

N

N

B

G

R

S

S

N

N

B

G

R

Beam displacement

direction

Magnetic flux

lines

6-pole

Beam motion producced by the

6- pole convergence magnet

S

S

S

N

N

N

R

B

G

S

S

S

N

N

N

R

B

G

Go to cover page

Forward

Back

Electrical Instructions (Continued)

Block Diagram

21

109B2 GS3 CM25

Go to cover page

Forward

Back

H V

V H

H

V

H. freq. : 30 - 97KHz

V. freq. : 50 - 160Hz

S-Capacitor Switch

Switching power freq.:

77kHz

CPU clock freq. : 12MHz

H/O

H

V

H/O

V/O

+190

90~264V

+80

+13

47~63Hz

+12

+5

-13

R

B

Pre -Amp

TDA4886A

Post-Amp

LM2405

OSD MTV

018N-27

Rotation

CRT

CPU

WT62P1/DDC1/2B

Linearity Control

DAF

S-

Capacitor

Horizontal

Deflection

Vertical

TDA8177F

Muting CKT

Sync Processor

TDA 4841

XXX

EHT/L4990A

X-RAY

Degaussing-

Ckt

Power

Supply

TEA1504

Video /B

DAC

SCL

SD

-6.3

DAC

HUNLOCK

Main /B

SDA/SCL

EEPROM

ST24C16

Function

Key/Cont

rol Board

& LED

Flying

cable 15

pin D-sub

G

Vedio-E

TDA4822

Control Panel Schematic Diagram & C.B.A

22

109B2 GS3 CM25

1891 A2

1892 A2

1893 A2

1894 A3

1895 A4

3891 A2

3892 A3

3893 A2

3894 A3

3895 A3

6891 A1

8891 A4

Go to cover page

Forward

Back

Video Panel (A) Schematic Diagram & Waveforms for Diagram (A)

23

109B2 GS3 CM25

Forward

Back

A1 7301-6

A3 7701-1

A1 7301-8

A3 7701-5

A1 7301-10

A4 1711-8

A2 7301-22

A2 7301-19

A4 1711-6

A2 7301-16

A3 7701-3

A4 1711-12

2 V/div AC

5 mS/div

50 V/div AC

5 mS/div

2 V/div AC

5 mS/div

50 V/div AC

5 mS/div

2 V/div AC

5 mS/div

50 V/div AC

5 mS/div

2 V/div AC

5 mS/div

2 V/div AC

5 mS/div

50 V/div AC

5 mS/div

2 V/div AC

5 mS/div

50 V/div AC

5 mS/div

50 V/div AC

5 mS/div

A5

7302-2

A5

7302-4

1 V/div AC

5 mS/div

1 V/div AC

5 mS/div

A5

7302-6

A7

7302-23

A7

7302-17

A7

7302-19

A7

7302-21

A6

7302-8

1 V/div AC

5 mS/div

2 V/div AC

5 uS/div

1 V/div AC

5 mS/div

1 V/div AC

5 mS/div

1 V/div AC

5 mS/div

2 V/div AC

5 mS/div

A1

A5

A6

A7

A7

A7

A8

A5

A5

A1

A1

A2

A2

A2

A3

A4

A4

A4

A3

A3

4.2V

1.2V

4.7V

4.1V

1.2V

1.2V

4.2V

4.2V

1.9V

1.9V

1.8V

56.5V

41.2V

4.8V

5.2V

5V

4.9V

48V

43.9V

-42V

4.7V

56.5V

57.8V

5V

4.2V

4.5V

3.2V

2.4V

5V

5V

4.5V

5V

5V

3.3V

Go to cover page

A

Video Panel (A) C.B.A

24

109B2 GS3 CM25

1301

D5

1703

B4

1711

C3

1712

C4

1713

C5

1714

A5

1715

C3

2324

D2

2348

E4

2721

B2

2723

C2

2724

A3

2725

D3

2731

B2

2732

A4

2733

C2

2751

D2

2752

A1

2753

B3

2762

D3

2772

D3

2773

B4

2775

B4

2776

B3

2778

E1

2779

C5

2780

C5

2783

E1

2785

B4

2786

C4

3310

E2

3325

D3

3332

D3

3333

E3

3344

D4

3345

D4

3346

D5

3349

E4

3351

E4

3352

D4

3353

D4

3354

D3

3356

E4

3357

E4

3358

E4

3359

D4

3701

A3

3703

D2

3704

D1

3705

D2

3706

D1

3713

D2

3716

D2

3718

C5

3719

C5

3720

D5

3721

C2

3722

B2

3723

B2

3724

A2

3726

B3

3727

A3

3728

B2

3729

D5

3731

B2

3732

B2

3733

A4

3734

A3

3736

A3

3737

A3

3738

B3

3751

D3

3752

D2

3753

A1

3754

C1

3756

A2

3757

A2

3758

D1

3760

B5

3771

B5

3772

D4

3773

A4

3775

C2

3779

A4

3781

B5

3784

D5

3785

D5

5301

D1

5303

E2

5701

D1

5702

C1

5721

B2

5732

B2

5752

C2

5771

B4

5772

D5

5773

E5

5779

C1

5781

B3

5784

C4

5786

A5

6301

E5

6302

E5

6303

E5

6304

E5

6711

B5

6722

B2

6732

B2

6751

D1

6752

D2

6771

D4

6772

A4

7301

E1

7302

E4

7303

E4

7304

E3

7322

D3

7701

C2

7702

A4

7721

A2

7722

A2

7731

A3

7732

A4

7751

A1

7752

A1

7761

E3

8301

D5

9783

D1

9791

C1

2301

E2

2302

E1

2304

E5

2305

E5

2306

E5

2307

C5

2308

D5

2309

E1

2310

D5

2311

D5

2312

E2

2316

D5

2317

D5

2318

D5

2319

E1

2322

E2

2323

E2

2325

D2

2326

E2

2341

E3

2342

E4

2343

E4

2344

E4

2345

E2

2346

E1

2347

E1

2349

A5

2350

E4

2702

C2

2722

C2

2726

C2

2728

C2

2739

B2

2740

C2

2760

E3

2761

E3

2763

E3

2771

C3

2777

A4

2781

E5

2782

E5

3301

D5

3302

D5

3303

D5

3305

E5

3306

E5

3307

C5

3309

E2

3311

E2

3312

D5

3313

D5

3314

D5

3315

E1

3316

D1

3324

E3

3326

E3

3327

E2

3328

E2

3329

D2

3330

D2

3331

E3

3334

E3

3335

E1

3336

E1

3337

E2

3338

E3

3339

E3

3341

D4

3342

E4

3343

E4

3347

E4

3348

E4

3350

E4

3355

E3

3360

E4

3361

E4

3362

E4

3363

E4

3372

E1

3376

E1

3378

C2

3379

E4

3380

E4

3702

B4

3707

D1

3725

A3

3730

D2

3735

A3

3740

E2

3741

C1

3742

C1

3743

C2

3744

B2

3745

C2

3755

A1

3761

E3

3762

E3

3763

E3

3764

E3

3765

E3

3767

D3

3776

B5

3777

B5

3778

B5

3782

A4

3783

B3

6721

B2

6724

C2

6731

B3

6734

B2

6754

D2

Go to cover page

Forward

Back

Click here for Video Panel C.B.A. (HMC)

Click here for Video Panel C.B.A. (SMC)

109B2 GS3 CM25

Video Panel (A) C.B.A. (HMC)

24-1

Go to cover page

Forward

Back

Click here for Video Panel (A) C.B.A. (CUS)

Click here for Video Panel (A) C.B.A. (SMC)

109B2 GS3 CM25

Video Panel (A) C.B.A. (SMC)

24-2

Go to cover page

Forward

Back

Click here for Video Panel (A) C.B.A. (CUS)

Click here for Video Panel (A) C.B.A. (HMC)

Main Panel (B1, B2, C) (C.B.A)

109B2 GS3 CM25

25

Go to cover page

Forward

Back

1101

G1

1104

E1

1106

G8

1111

F1

1113

G2

1114

F4

1401

B5

1603

B7

1605

A6

1801

E8

1802

F9

2101

F1

2102

E2

2103

E2

2104

F1

2105

F2

2106

F1

2109

F5

2111

F4

2112

G5

2114

F3

2115

D1

2120

F6

2122

G5

2123

G5

2128

G3

2150

E3

2152

E2

2154

E2

2156

E4

2157

E4

2158

F4

2160

E4

2161

E5

2162

E5

2163

E2

2164

D2

2165

E2

2166

F6

2167

E5

2170

F5

2172

F6

2401

C7

2403

D6

2404

C6

2405

C6

2406

C6

2407

C6

2408

C7

2409

C7

2410

B5

2431

E1

2432

D1

2433

C1

2434

D1

2435

B1

2436

B1

2437

B1

2441

C1

2442

C1

2443

B1

2444

C1

2445

C1

2446

D1

2501

C8

2502

D5

2503

C7

2504

C7

2505

C8

2506

B8

2507

B8

2508

C8

2509

C9

2510

E6

2511

D9

2512

C9

2513

C8

2514

C8

2515

C8

2516

C8

2518

D8

2519

C8

2520

C8

2521

E6

2522

D8

2523

E6

2525

C7

2526

A1

2571

C1

2572

D1

2575

A3

2576

A3

2577

C3

2578

A1

2581

A1

2582

A1

2601

A5

2602

A5

2603

A5

2604

D3

2605

D4

2606

C4

2607

C5

2608

B5

2609

D4

2610

C3

2611

C4

2612

D4

2613

B3

2614

B3

2615

B3

2616

B5

2617

C4

2618

B6

2619

A5

2620

A9

2621

A9

2622

A8

2623

A9

2624

A7

2625

A9

2626

B8

2627

A7

2628

B9

2629

A6

2630

B6

2631

C9

2632

A8

2633

A3

2634

A8

2635

A6

2636

A9

2637

B9

2638

A8

2639

A8

2640

B6

2641

B6

2642

A8

2644

E6

2645

A9

2646

B6

2651

B8

2652

B8

2801

E7

2802

E7

2803

D8

2804

E8

2805

E8

2806

E8

2808

F9

2809

F7

2810

G7

2811

G7

2812

F7

2816

F8

2817

E8

2819

G8

2820

G8

2821

D7

2822

F6

2823

B8

2824

E9

2825

E9

2826

G8

3101

F1

3106

G2

3107

G3

3108

G2

3110

G4

3111

G4

3112

F3

3113

G4

3114

G5

3115

G3

3116

G3

3117

G3

3118

G3

3119

G4

3120

G3

3121

G6

3122

G6

3123

G5

3124

G6

3125

G5

3126

F5

3127

G7

3128

G5

3129

G5

3130

E1

3131

G5

3132

F6

3133

G4

3134

G5

3135

E5

3137

G1

3138

G1

3139

E1

3151

E3

3152

E2

3153

D2

3154

E2

3156

E6

3159

E5

3160

D2

3161

E2

3162

F5

3163

E5

3165

E4

3166

D1

3167

F5

3168

E6

3170

F5

3171

F5

3172

E5

3173

F5

3174

E5

3175

E5

3176

F6

3177

E6

3401

C7

3402

C7

3403

C7

3404

B6

3405

B6

3406

C6

3407

C6

3408

C6

3409

B6

3410

C6

3411

C6

3412

C6

3413

C6

3415

C6

3430

D1

3431

D1

3432

D1

3433

D1

3434

D1

3435

D1

3436

D1

3437

D1

3438

D1

3441

C1

3442

B1

3443

B1

3444

C1

3445

B1

3446

B1

3447

B1

3448

B1

3449

A1

3451

C1

3452

C1

3453

C1

3454

C1

3455

C1

3501

D6

3502

E6

3503

E6

3504

D6

3505

D6

3506

D7

3507

D8

3508

C8

3509

D8

3510

C9

3511

D8

3512

C9

3513

D8

3514

D6

3515

C7

3516

C7

3517

E6

3518

D7

3519

D9

3520

C8

3521

D6

3522

A6

3523

B9

3524

C9

3525

B9

3527

D8

3528

C7

3529

C7

3530

C7

3531

C7

3533

D7

3534

C7

3536

C9

3537

D9

3538

B9

3571

C2

3572

C1

3573

D1

3574

D1

3575

D2

3576

D1

3577

D2

3578

A2

3581

C2

3582

B3

3583

C3

3585

A3

3586

A4

3587

A3

3590

A1

3591

A1

3592

A1

3593

A1

3594

A1

3595

A1

3596

A1

3597

A1

3598

A1

3601

A6

3602

A5

3603

B6

3604

A5

3605

B4

3606

B4

3607

D5

3608

D3

3609

C4

3610

C5

3611

C5

3612

C5

3613

B5

3614

D3

3615

D3

3616

D7

3617

D6

3618

C5

3619

D4

3620

D4

3621

A9

3622

B6

3623

B6

3624

B6

3625

B6

3626

A9

3627

B6

3628

B6

3629

B6

3630

A4

3631

A5

3632

A9

3633

A9

3634

B9

3635

B9

3636

A9

3637

A9

3638

A8

3639

A8

3640

A8

3641

B8

3642

A9

3643

B9

3644

B8

3645

C8

3646

A9

3647

B9

3648

A4

3649

A4

3653

A6

3654

A2

3655

A7

3657

A6

3658

B8

3659

A3

3660

B7

3661

B7

3662

B9

3669

B7

3672

A5

3673

A8

3675

A6

3676

A6

3677

A9

3681

C7

3682

B7

3683

B7

3684

C7

3685

C7

3686

B7

3687

A5

3688

B7

3691

B9

3692

B9

3693

B8

3694

B8

3699

B9

3801

F8

3802

E7

3803

E7

3804

D8

3805

E7

3806

E8

3807

E9

3808

E8

3809

A9

3810

A9

3811

A9

3812

B9

3813

D9

3815

E9

3816

E9

3818

E9

3819

D7

3821

E7

3822

E7

3824

E7

3825

E7

3826

E7

3827

E7

3828

F8

3829

F8

3830

F8

3831

F8

3832

E7

3833

F9

3834

E8

3835

F6

3836

F9

3837

F7

3838

E9

3839

F7

3840

F7

3841

F7

3842

F7

3843

F7

3844

F9

3845

F9

3846

F9

3847

F9

3848

F9

3849

F9

3850

F9

3851

E9

3852

E9

3853

E8

4101

G4

4151

E6

4401

C5

4601

D1

4602

B7

4603

A3

4604

B8

5101

F4

5102

F2

5103

G2

5104

G1

5105

E1

5106

G3

5107

G2

5112

F4

5151

D3

5152

D3

5153

D3

5154

D3

5155

E5

5156

D4

5157

D3

5158

D3

5571

D2

5572

B2

5573

B2

5601

A4

5602

C5

5603

B4

5604

B5

5606

A5

5608

B3

5609

A7

5610

C3

5801

E8

5802

E7

5803

F8

6102

G3

6103

F4

6107

F5

6108

F3

6109

G3

6113

E1

6115

G5

6116

G4

6117

G5

6118

G5

6121

G6

6123

F5

6124

F5

6125

F6

6148

E4

6149

E3

6151

E3

6152

E3

6153

E4

6154

E4

6155

E4

6156

D3

6157

E2

6158

D5

6159

D2

6161

D2

6162

F5

6163

E5

6164

E5

6165

G5

6166

F6

6401

C6

6402

C6

6403

D6

6431

D1

6432

C1

6433

D1

6434

B1

6435

B1

6436

B1

6437

B1

6438

B1

6439

B1

6501

C9

6502

C7

6503

C7

6504

D8

6505

D7

6506

D7

6507

D9

6508

B9

6509

D9

6511

C7

6512

D6

6571

C2

6572

C1

6573

C2

6574

A3

6575

B3

6581

A1

6582

A2

6583

A1

6584

A2

6585

A1

6601