马兰士MARANTZ DV3100N1B音响电路图

)

)

)

)

)

)

)

)

)

)

DVD Player

TABLE OF CONTENTS

SECTION

PAGE

1. TECHNICAL SPECIFICATIONS ................................................................................................................ 1

2. PRODUCT SAFETY SERVICING GUIDELINE FOR VIDEO PRODUCTS ................................................ 2

/SERVICING PRECAUTIONS .................................................................................................................... 3

3. INFORMATIONS ........................................................................................................................................ 4

4. SERVICING HINT....................................................................................................................................... 5

5. REGIONAL CODES ................................................................................................................................... 6

6. LOCATION OF CUSTOMER CONTROLS ................................................................................................. 7

7. DISASSEMBLY ....................................................................................................................................... 2-2

8. EXPLODED VIEWS/PARTS LIST ........................................................................................................... 2-4

9. ELECTRICAL TROUBLESHOOTING GUIDE ......................................................................................... 3-2

10. BLOCK DIAGRAMS .............................................................................................................................. 3-12

11. CIRCUIT DIAGRAMS ............................................................................................................................ 3-18

12. PRINTED CIRCUIT DIAGRAMS/ELECTRICAL PARTS LIST .............................................................. 3-38

13. DECK MECHANISM ................................................................................................................................ 4-1

Service

Manual

DV3100 /N1B

Please use this service manual with referring to the user guide (D.F.U) without fail.

R

DV3100

304W855020 ACT

3120 785 22450

First Issue:2000.10

DVD PLAYER DV3100

STANDBY

STANDBY/ON

POWER

OPEN/CLOSE

STOP

PAUSE

PLAY

DV3100

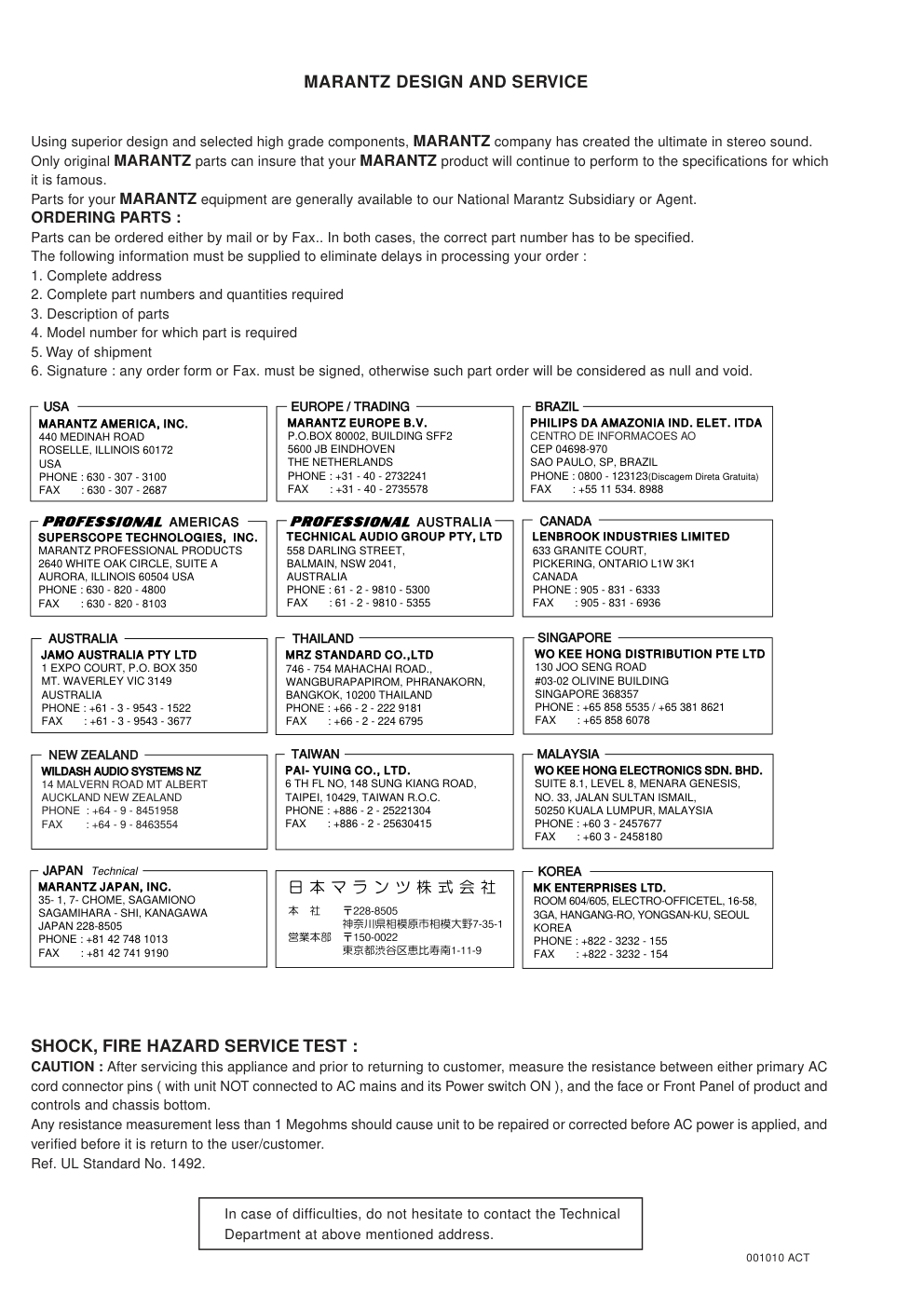

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

001010 ACT

USA

MARANTZ AMERICA, INC

MARANTZ AMERICA, INC.

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

BRAZIL

PHILIPS DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123(Discagem Direta Gratuita)

FAX : +55 11 534. 8988

JAPAN Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX

: +64 - 9 - 8463554

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

130 JOO SENG ROAD

#03-02 OLIVINE BUILDING

SINGAPORE 368357

PHONE : +65 858 5535 / +65 381 8621

FAX : +65 858 6078

1

TECHNICAL SPECIFICATIONS

DVD VIDEO PLAYER

Power supply

AC 120V, 60Hz(U1B)

/AC100V, 50/60Hz(F1N)

/AC220~240V, 50Hz(N1B)

/110~240V, 50Hz(K1G, A1B)

Power consumption

16W

Mass

3.2kg(7.1lbs)

External dimensions

430 x 88 x 215 (W x H x D)

Signal system

NTSC 525/60, PAL 625/50

Laser

Semiconductor laser, wavelength 650nm

Frequency range (audio)

4Hz to 20 kHz

Signal-to-noise ratio (audio)

More than 100 dB (EIAJ)

Dynamic range (audio)

More than 95 dB (EIAJ)

Harmonic distortion(audio)

0.008%

Wow and flutter

Below measurable level (less than +0.001%(W.PEAK)) (EIAJ)

Operating conditions

Temperature : 5˚C(41˚F) to 35˚C(95˚F),

Operation status : Horizontal

OUTPUTS

Video output

1.0V(p-p), 75Ω, negative sync., RCA jack x 1 / SCART

S-video outputs

(Y)1.0V(p-p), 75Ω, negative sync.,Mini DIN 4-pin x 1

(C)0.286V(p-p), 75Ω

Audio output(digital audio)

0.5V(p-p), 75Ω, RCA jack x 1

Audio output(analog audio)

2.0Vrms (1kHz, 0dB), 330Ω, RCA jack (L, R) x 1 / SCART

*Designs and specifications are subject to change without notice.

2

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFAC-

TURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR

ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTEC-

TION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS, FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD), AND REPLACE IF NECESSARY.

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUDING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIR-

CUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABI-

NET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HAN-

DLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLT-

METER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESIS-

TOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CON-

DUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIAN-

GLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PER-

SONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTEN-

TIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PIC-

TURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERA-

TION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PIC-

TURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIR-

CUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIR-

ABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS AN X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA-

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY. WE SUGGEST THAT YOU AND YOUR SERVICE ORGA-

NIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGU-

LATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCE-

DURE AND THAT THE HIGH VOLTAGE READING BE RECORDED ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IT IS NECESSARY TO LOCATE THE CAUSE OF EXCES-

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE-

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBY-

HOLE OR CLOSELY FITTING SHELF SPACE, OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIA-

TORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DEC-

ORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMER-

CIAL MOUNTING KIT, MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS. A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM. BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZ-

ARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS.

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SIN-

GLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

3

SERVICING PRECAUTIONS

CAUTION : Before servicing the DVD covered by this service

data and its supplements and ADDENDUMS, read and follow

the SAFETY PRECAUTIONS. NOTE : if unforeseen circum-

stances create conflict between the following servicing pre-

cautions and any of the safety precautions in this publica-

tions, always follow the safety precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this DVD or any of

its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this DVD and/or any of its

electrical assemblies unless all solid-state device heat

sinks are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resist-

ance between each blade of the attachment plug and acces-

sible conductive parts (Note 1) should be more than 1M-ohm.

Note 1 : Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor compo-

nent or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commer-

cially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a GROUNDED-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec-

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static elec-

tricity sufficient to damage an ES device.)

4

3. INFORMATIONS

REGION CODE

THE DISCS THAT THE DV3100 CAN HANDLE

The following discs can be played back with a DV3100.

Note: The regional code of the discs must meet to the regional

code of the product.

DVD INFORMATION

Below is a glossary of the new terms related to DVD.

Title:

A disc may have more than one story/movie on it, so each

story/movie is called a “title”.

For example, if there are 2 movies on the disc, they are

separated into Title 1 and Title 2.

Chapter:

A title may also be separated into chapters.

For example, a movie (title) may be separated into 3 scenes

(chapters).

Subtitles:

DVDs are recorded with up to 32 different subtitle languages.

If a disc has more than one subtitle language, you can select

the subtitle language that you want to read.

Soundtrack language:

DVDs are recorded with up to 8 different soundtrack languages.

If a disc has more than one language, you can select the

soundtrack language that you want to listen to.

Multi-angles:

On some DVDs, scenes have been filmed from different angles

(up to a maximum of 9). On these discs, you can select the

angle that you want to watch. Please refer to the DVD’s manual

to see which scenes have multi-angles.

Parental guide:

Some discs have restriction levels that allow you to cut scenes

or prevent playback of discs that have contents that you do

not want children to watch.

disc

mark

playback capability

size

side

DVD

Audio/Video

12 cm

single/double

8 cm

CD

Audio

12 cm

single

8 cm

VERSION

REGION CODE COUNTRY

/N1B

2

EUROPE

/F1N

2

JAPAN

/A1B

4

AUSTRALIA

/U1B

1

USA/CANADA

Title 1

Title 2

Chapter

3

Chapter

1

Chapter

2

Chapter

3

Chapter

1

Chapter

2

5

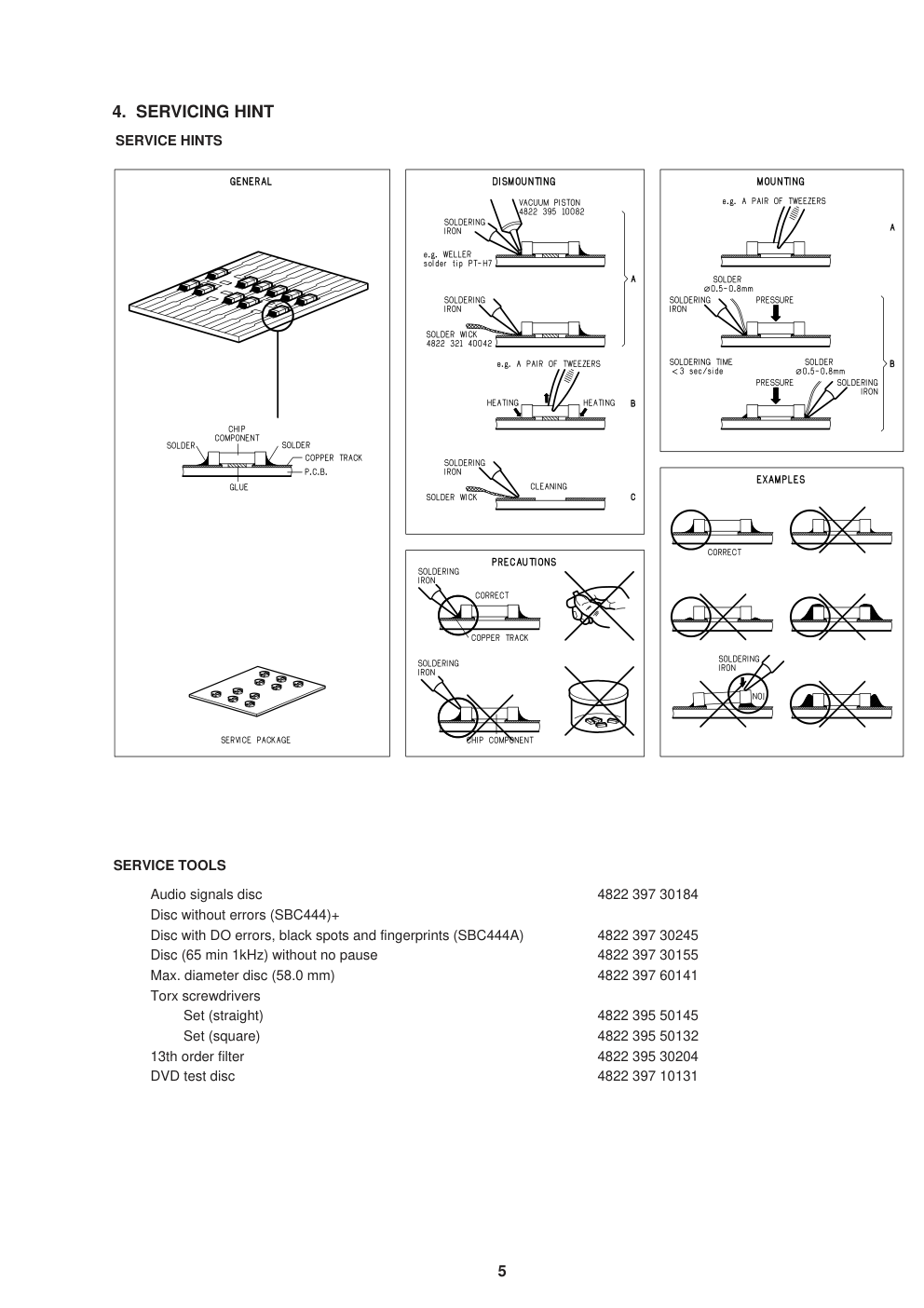

SERVICE TOOLS

Audio signals disc

4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A)

4822 397 30245

Disc (65 min 1kHz) without no pause

4822 397 30155

Max. diameter disc (58.0 mm)

4822 397 60141

Torx screwdrivers

Set (straight)

4822 395 50145

Set (square)

4822 395 50132

13th order filter

4822 395 30204

DVD test disc

4822 397 10131

SERVICE HINTS

4. SERVICING HINT

6

REGIONAL CODES

1

2

2

2

5

5

4

4

3

6

Map of DVD Regions

What are "regional codes"?

Motion picture studios want to control the home release of movies in different countries because theater releases arenít

simultaneous (a movie may come out on DVD in the US when itís just hitting screens in Europe). Therefore they have

required that the DVD standard include codes which can be used to lock out the playback of certain discs in certain geo-

graphical regions. Players sold in each region will have that regionís code built into the player. The player will refuse to play

these "region coded" discs which are not allowed in the region. However, regional codes are entirely optional. Discs without

codes will play on any player in any country. Some studios have already announced that only their new releases will have

regional codes. There are six regions:

1. United States and Canada

2. Europe and Japan

3. Far East (except Japan & China)

4. South America and Oceania

5. Africa and the Middle East

6. China (except Hong Kong)

7

LOCATION OF CUSTOMER CONTROLS

DVD PLAYER DV3100

STANDBY

STANDBY/ON

POWER

OPEN/CLOSE

STOP

PAUSE

PLAY

TITLE

CD

PROG. NKS

RANDOM ALL A

B

CHP/TRK

DVD

MODEL NO.DV3100

COAXIAL

OUT

DIGITAL

OUT

S-VIDEO

OUT

AUDIO

OUT

VIDEO

L

R

PAL

NTSC

AUTO

A/V EUROCONNECTOR

TV

F RO N T PA N E L

DISPLAY WINDOW

R E A R PA N E L

POWER INDICATOR

POWER BUTTON

DISPLAY WINDOW

REMOTE SENSOR

OPEN/CLOSE BUTTON

SKIP/SCAN BUTTONS

DISC TRAY

PLAY BUTTON

PAUSE BUTTON

STOP BUTTON

ANGLE ICON INDICATOR

TITLE NUMBER INDICATOR

S-VIDEO OUT JACK

AV-EURO CONNECTOR

VIDEO OUT JACK

PAL/NTSC

CHAPTER/TRACK NUMBER INDICATOR

TOTAL PLAYING TIME/ELAPSED

TIME INDICATORS

AUDIO OUT1(L/R) JACKS

POWER CORD

Connect to an AC 220~240V, 50Hz

outlet only.

COAXIAL DIGITAL AUDIO OUT JACK

OPERATING STATUS INDICATOR

PROGRAM INDICATOR

DVD INDICATOR

REPEAT PLAYBACK

MODE INDICATORS

CD INDICATOR

RANDOM INDICATOR

8

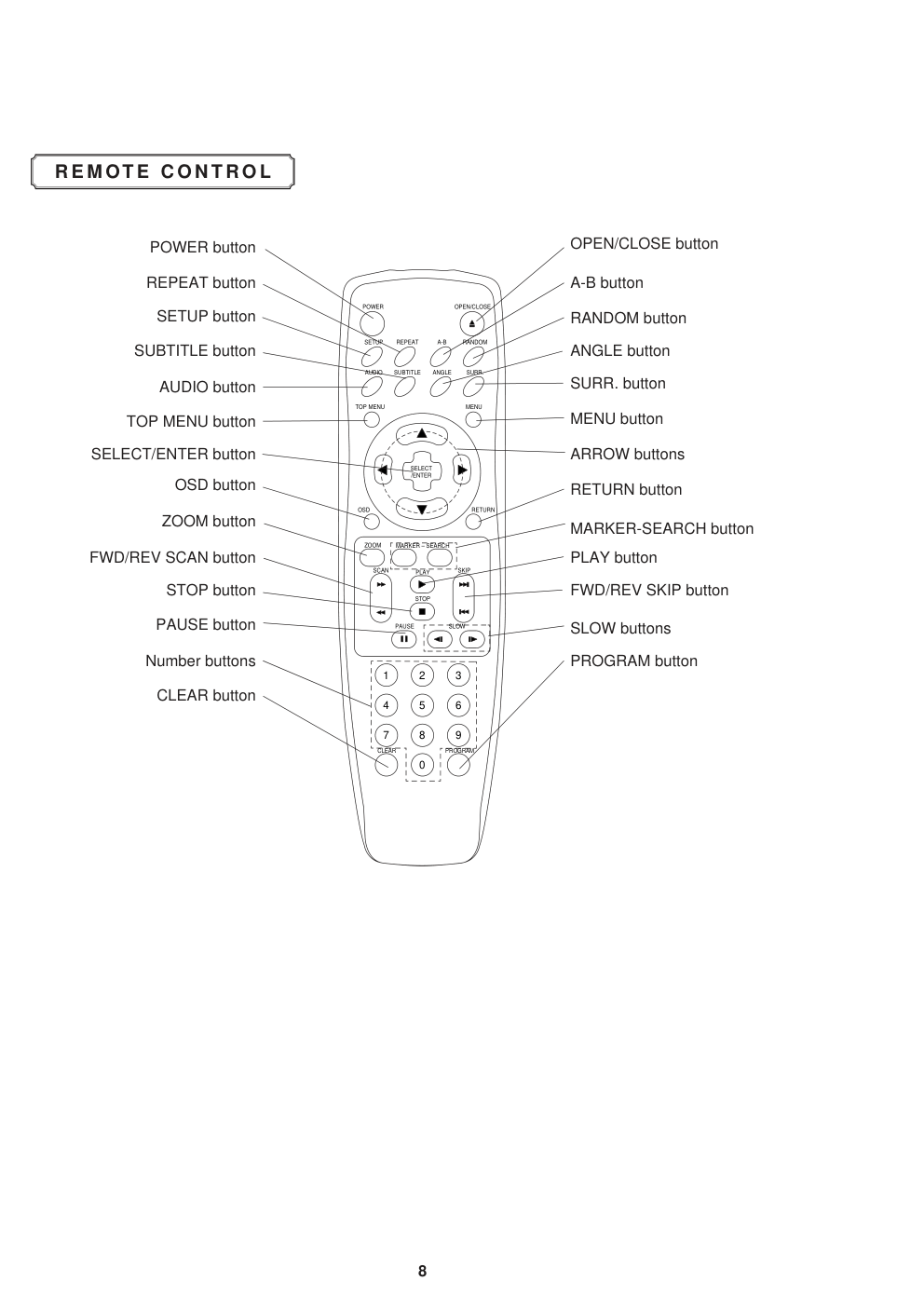

R E M OT E C O N T RO L

POWER button

STOP button

AUDIO button

FWD/REV SCAN button

REPEAT button

TOP MENU button

MENU button

ARROW buttons

RETURN button

PLAY button

FWD/REV SKIP button

SLOW buttons

MARKER-SEARCH button

OPEN/CLOSE button

RANDOM button

A-B button

ANGLE button

SURR. button

OSD button

ZOOM button

SELECT/ENTER button

SUBTITLE button

SETUP button

2

3

1

5

6

4

8

0

9

7

PROGRAM

SKIP

SCAN

PLAY

ZOOM

OSD

TOP MENU

MENU

ANGLE

SELECT

/ENTER

SURR.

SUBTITLE

AUDIO

A-B

RANDOM

REPEAT

POWER

OPEN/CLOSE

SETUP

RETURN

STOP

PAUSE

MARKER – SEARCH

SLOW

CLEAR

PAUSE button

Number buttons

CLEAR button

PROGRAM button

2-1

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

1. DISASSEMBLY.........................................................................................................................2-2

CABINET DISASSEMBLY ............................................................................................................2-2

CIRCUIT BOARD DISASSEMBLY................................................................................................2-3

2. EXPLODED VIEWS.................................................................................................................2-4

1. Cabinet and Main Frame Section ...........................................................................................2-4

2. Packing Accessory Section ....................................................................................................2-5

2-2

DISASSEMBLY

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded patrs and fine pitch screws used to secure

metal parts. If they are used improperly, the screw holes will be easily damaged and the parts can not be fixed.

Top Case

(A)

(A)

(A)

(A)

(A)

(A)

(A)

Tray Door

Disc Tray

Front Panel

Stopper

Stopper

(B)

(B)

CABINET DISASSEMBLY

1. Top Case

1. Release 7 screws (A). (See Fig. 2-1)

2. Lift the top case with holding the back of it,

and remove it in the direction of the arrow

Fig. 2-1

Fig. 2-2

Fig. 2-3

3. Front Panel

1. Eject the disc tray. (See Fig. 2-2)

2. Remove the tray door. (See Fig. 2-2)

3. Release 2 screws (B).

4. Pull the front panel toward you while pressing

7 stoppers to disengage, and remove the front

panel. (See Fig. 2-3)

(A)

Press open/close button to open the tray. If the

tray doesn't work, insert and push a small screw-

driver in the emergency eject hole (A) at the right

side. Then the tray comes out. After the first

centimeter it is possible to pull the tray out by

hand. Release the door cover of the tray.

REMARK: Before disassemble the front panel.

2.Tray Door

1.Eject the disc tray.

2.Lift up the tray door in the direction of the

arrow.

2-3

Main Circuit Board

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

Power Code

Interface

Circuit

Board

(D)

(D)

Key

Circuit Board

(E)

(E)

(E)(E)

Fig. 2-4

Fig. 2-5

1. Disassembling of Main Circuit Board

and Interface Board

1. Remove the top case.(See Fig. 2-1)

2. Remove 12 screw (C).

3. Remove the deck from Main Circuit Board.

4. Remove Main Circuit Board from Interface

Board.

5. Remove 2 screw (D).

6. Remove Interface Board from the chassis.

CIRCUIT BOARD DISASSEMBLY

Note: Before removing the main circuit board, be sure to shortcircuit the laserdiode output land.

After replacing the main circuit board, open the land after inserting the flexible connector.

(Refer to Mechanism Disassembly)

2. Digitron and Key Circuit Board

1. Remove the front panel.(See Fig. 2-3)

2. Release 4 screws (E), and remove the digitron

circuit board.

2-4

EXPLODED VIEWS

1. Cabinet and Main Frame Section

280

465

467

465

465

463

A46

463

463

279

275

332

PBP00

PBT00

283

260

467

300

467

A48

A43

250

462

462

463

463

452

452

285

Jack

Scart

A

5

4

3

2

1

B

C

D

2-5

2.Packing Accessory Section

BATTERY

808

PACKING SHEET

804

PACKING

803

811

812

OWNER'S MANUAL

VIDEO

AUDIO

801

REMOTE CONTROLLER

900

BOX CARTON

802

PACKING

803

POS.

VERS.

PART NO.

DESCRIPTON

PART NO.

NO.

COLOR

(ANAM)

(MJI)

250

nsp

TOP COVER (BLACK)

nsp

260

/N1B

nsp

CHASSIS ASSY MAIN (/N1B)

nsp

275

nsp

HOLDER MAIN PCB

nsp

279

nsp

HOLDER CONNECTOR

nsp

280

/N1B

9965 000 06951 PANEL ASSY FRONT (/N1B)

304W248510

283

/N1B

9965 000 06952 DOOR ASSY (BLACK)

304W063500

300

/N1B

9965 000 06953 MAINS CORD (/N1B)

*YC000510R

332

nsp

PLATE MAIN GND

nsp

429

nsp

SCREW B-TITE

nsp

430

nsp

SCREW +D2.0 6MM

nsp

SWRCH16A/NIY 4.5MM

430

nsp

SCREW +D2.0 6MM

nsp

SWRCH16A/NIY 4.5MM

431

nsp

SCREW +D2.0 6MM

SWRCH16A/ZNBK 4MM 1

nsp

432

nsp

SCREW MACHINE

nsp

432

nsp

SCREW MACHINE

nsp

452

nsp

SCREW SPECIAL

nsp

462

nsp

SCREW DECORATION

nsp

463

nsp

SCREW SPECIAL

nsp

465

nsp

SCREW SPECIAL (3X10 BK)

nsp

467

nsp

SCREW SPECIAL (3X8 BK)

nsp

POS.

VERS.

PART NO.

DESCRIPTON

PART NO.

NO.

COLOR

(ANAM)

(MJI)

801

/N1B

9965 000 06954 USER GUIDE (/N1B)

304W851310

802

nsp

BOX

nsp

803

nsp

PACKING

nsp

804

nsp

SHEE

nsp

808

nsp

BATTERY AAA(R03)

nsp

811

nsp

PHONO CORD (YL)

nsp

812

nsp

PHONO CORD (RD/WH)

nsp

900

9965 000 06955 REMOTE CONTROLLER

ZK304W0010

3-1

SECTION 3

ELECTRICAL

CONTENTS

ELECTRICAL TROUBLESHOOTING GUIDE......................................................................3-2

1. Power(SMPS) Circuit...............................................................................................................3-2

2. µ-com Circuit...........................................................................................................................3-3

3. MPEG Circuit ...........................................................................................................................3-6

4. Front Circuit(Digitron & Key) .................................................................................................3-7

5. RF/Servo Circuit ......................................................................................................................3-8

BLOCK DIAGRAMS ..................................................................................................................3-12

1. Overall Block Diagram..........................................................................................................3-12

2. Power (SMPS) Block Diagram..............................................................................................3-13

3. RF/CD DSP/DVD DSP/DVD servo Block Diagram..............................................................3-14

4. Audio Block Diagram ............................................................................................................3-15

5. MPEG Block Diagram ..........................................................................................................3-16

6. µ-COM Block Diagram..........................................................................................................3-17

CIRCUIT DIAGRAMS ...............................................................................................................3-18

1. Power (SMPS) Circuit Diagram ............................................................................................3-18

2. DVD DSP Circuit Diagram.....................................................................................................3-20

3. Drive & RF Circuit Diagram...................................................................................................3-22

4. MPEG Circuit Diagram ..........................................................................................................3-24

• WAVEFORMS...........................................................................................................................3-26

5. Audio DM & 5.1CH Circuit Diagram .....................................................................................3-28

6. µ-COM/Expander...................................................................................................................3-30

7. DIGITRON & Key Circuit Diagram ........................................................................................3-32

8. Jack Circuit Diagram.............................................................................................................3-34

PRINTED CIRCUIT DIAGRAMS ...........................................................................................3-36

1. MAIN P.C.BOARD...................................................................................................................3-36

2. POWER,A/V,FRONT P.C.BOARD...........................................................................................3-38

3. KEY P.C.BOARD ....................................................................................................................3-40

4. POWER LED P.C.BOARD ......................................................................................................3-41

3-2

ELECTRICAL TROUBLESHOOTING GUIDE

No 5V_D

or 5V_A .

No 5.2VA.

Is 5.2VA section working?

Is oscillation present at the

Base of Q108?

Replace Q108.

Check L103, C116, 117.

Replace R111.

Replace BD101.

(Bridge rectifier)

Check Fuse(F101).

Is R111 1Ω?

Check D105.

Replace Q101, 102.

Is 5.2V applied to IC102

Pin 1?

Is there a DC voltage at the

(+) terminal of BD101?

Check R127, 128.

(SHUTDOWN CKT)

1. Power(SMPS) Circuit

No VF+

Is 5.2VA section working?

Replace D109.

Is oscillation present at the

anode of D109?

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

A.

B.

NO

NO

NO

3-3

Replace IC506.

Refer to Front Part

Check short

Reconnect it.

2. µ-COM Circuit

A. No Power

Does Logo appear

on the screen?

Is oscillation of

X501 normal?

Are IC503 Pins 14, 288

and 29 normal?

Do all five Bars appear?

Does Bar appear at FLD?

Is P5901

connected normally?

Is P5901 Pin 24 normal?

The

waveform on A[00:21]

and D[00:15] of IC501

normal?

Are IC506 Pins 7, 8 normal?

Replace Main B/D.

Check the oscillation

Check short.

OK

Replace IC501

or IC503.

Check power.

(Refer to power)

If power is

normal

OK

POWER ON

1

1

YES

YES

YES

YES

YES

YES

YES

YES

A

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

A

3-4

B. Audio abnormal

D. Open/Close abnormal

Check the

connection of P5901.

Check IC501 Pins 13, 14.

Check Audio jack.

YES (If OK)

YES

NO

NO

YES

YES (If OK)

YES

YES (If OK)

YES (If OK)

YES (If OK)

Check PLL FC of MPEG part.

Refer to Audio part.

Refer to MPEG part.

Replace B/D.

Check Front.

Reconnect it.

Refer to SERVO part.

Check the connection of MD.

AUDIO ABNORMAL

OPEN/CLOSE ABNORMAL

C. Video abnormal

Check Video jack.

YES (If OK)

YES (If OK)

YES (If OK)

YES (If OK)

Refer to Video part.

Refer to Encoder part.

Refer to MPEG part.

Replace B/D.

VIDEO ABNORMAL

3-5

E. Picture abnormal

Check the disc.

If OK

YES (If OK)

YES (If OK)

Refer to Servo part

Check PLL IC of MPEG part

Check DSP

Check MPEG

YES (If OK)

Replace B/D

PICTURE ABNORMAL

F. Disc Error

Check Disc

YES (If OK)

YES (If OK)

Refer to Servo part

Replace B/D

DISC ERROR

3-6

Power is on

Does LG Logo appear

on the screen?

Does the

moving picture of the DVD Disc

play on the screen

normally?

Is MPEG data signal normal?

Is error signal normal?

Is MPEG data signal normal?

Is Clock normal?

Does the audio

sound output from MPEG

decoder?

Does the

moving picture of the video

CD play on the screen

normally?

Does the audio sound

output normally?

END

Check power & clock.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check clock signal

Check clock signal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

OK

OK

OK

OK

NO

NO

NO

NO

NO

3. MPEG Circuit

_ OPTION

_ If included VCD function.

3-7

NO

NO

NO

START

Does remote control

work normally?

Do all the

buttons work

normally?

Check waveform of

IC901 Pin 13.

Check waveform

of IC901 Pin 2.

Is Digitron on normally?

LED ON?

Check waveform

of IC901 Pin 6.

Is oscillation of

X901 normal?

Is waveform of IC901

Pin 76 normal?

Check waveform

of IC901 Pin 13.

Does pulse

waveform of RC901 Pin 1

appear?

Is IC901

Pin 24 connected to

RC901 Pin 1 ?

Is RC901 Pin 2 5V?

Power on.

Check and replace

R903,R912, R904, R905,

R941, R906, R907.

Solder defective parts again.

Solder defective parts

Replace Q901.

Solder Key part.

Check Power.

Replace IC902.

Replace IC901.

Replace LED901.

Replace RC901.

Re-solder.

Recheck

Replace IC901.

Complete repairing Front B/D.

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

CD

4. Front Circuit (Digitron & key)

3-8

Does signal pulse

input to IC201 Pins 58, 59 when

the power is on?

Does signal goes

"High" to IC201 Pin194 when the

power is on?

Does

TTL pulse output to

IC201 Pins 140, 142?

Does

33.8688MHz clock input

to IC201 Pin 63?

Is IC201

Pins 83, 84, 88, 89 voltage

about 2.2V?

Replace IC201

(IC206 soldering or IC defect).

Check power circuit.

Check "2.µ-COM Part".

Replace X301 or IC304

(30MHz clock defect)

CHECK POINT(General)

5. RF/Servo Circuit

A.

END

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

3-9

Does tray open or close?

Does the pick-up

slide inner or outer

track?

Fig.1. SLED Driver waveform

Fig.2. Focus Driver waveform

Does

the voltage change

at PMD04 Pins 1, 2 more than

2V on the basis of

3.8V?

Pressing

the open/close key

repeatedly, check the voltage of IC2M1

Pins 13, 14 change

0V to 5V

Does

PMD03 Pin 7 change

high to low?

Does

the pick-up lens move up

and down?

Check Focus Driver output.

(IC201 Pin 83, IC2M1 Pins 37, 38)

Check SLED Driver output.

IC201 Pin 88 IC2M1 Pins 28, 29.

IC201 Pin 88 no output : IC201 is defective

IC2M1 Pin 18 no output : IC2M1 is defective

IC201 Pin 83 no output : IC201 is defective

IC2M1 Pins 1, 2 no output : IC2M1 is defective

DECK assembly is defective.

Slide the pick-up to

inner track.

.Power on

Check loading Part.

Push Pick-up to inner track to

the end by hand.

DECK assembly is defective.

(Limit sw)

check µ-COM Part.

Replace IC2M1.

No disc

B.

END

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

3-10

FOCUS ON?

Check

the focus error moving the

lens up and down.

(IC2A1 Pin 42)

Does the

TTL level change at IC201

Pin 78 and 132 moving

the lens?

Does the disc turn?

IC201 Pin169 is "High"?

Is OK the track jump.

Does the signal

pulse appear at IC2A1 Pins

39, 29?

Does the screen appear?

OPEN/CLOSE

Replace µ-COM or IC201.

Replace IC201.

Check IC2A1 Pin 11,12,13,14

in DVD Mode

Fig.3. FOCUS ERROR waveform

IC201 no output : Pick-up is defective.

Check IC201 and IC2M1 when PMD03 Pin 6 is abnormal

Check IC2M1 Pin 21, PMD03

Pin 6 turn when the IC2M1

Pin 21 is less than 2.2V.

Check A

Video Part is defective.

Check "5.MPEG Circuit."

Check "7.OSD/Video Circuit."

Replace µ-COM part.

IC2A1 is defective.

DISC IN

C.

END

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

3-11

Is the eye-pattern vivid?

Does the

sawtooth waveform emit

at IC2A1 Pin 41?

Does the 1.6V emit?

Check RF Eye-Pattern.

RF : 1.5-1.6V(IC2A1 Pin 57)

Fig.5. RF

waveform

Check IC2A1 Pins 5, 6, 7, 8.

No signal: Pick-up is defective

Replace IC201.

Check IC201 Pin84.

No signal at IC201 : IC201 is defective

• Check IC201 Pin 162.

• Check the clock at the IC201 Pins 28, 30.

• Both are normal : IC201 is defective

Replace IC2A1.

CHECK A

D.

END

NO

NO

NO

NO

YES

YES

YES

YES

3-12

BLOCK DIAGRAMS

1. Overall Block Diagram

DISC

SPINDLE

MOTOR

LOADING

MOTOR

Focus, tracking sled

VF+

VF-

-24V

8V

5.2VA

5V_A

5V_D

3.3V_M

3.3V

2.5V

8V

A.GND,D.NGD,M.GND

loading drive

spindle

loading

CD,DVD:A,B,C,D,E,F

MIRR,TZC

DVD_LDQM,DVD_SD,CSI

DVD_MA[0:11]

DVD_MD[0:15]

DVD_SD_CAS,

DVD_SD_RAS

DVD_SD_CLK

DVD_MWE

DVD_DATA[0:7]

DVD_SD_CSO,

DVD_UDQM

ICADDR[0:8]

ICDATA[00:15]

SDCLKI, ZISENB

REQZI

3.38688MHz

DA_DATA,

DA_LRCK,

DA_BCK

D[00:07]

S_CLK,S_DATA,

DPLL_L

IIC_DATA,

IIC_CLK

A[00:02]

DA_XCK

CVBS,

Y,C

Y(G),

PB(B)

PR(R)

CVBS,Y,C

Y(G)PB(B),PR(R)

27MHz

FE,TE,RFRP,SBADD,DVD/CD RF

TEBAL,FEBAL,

DPOCTL,EQF,EQB

MON,SPINDLE_DRV

FDO,TDO,

FMO

AC100-

240V,

50~

60Hz

FL DISPLAY

REMOCON

RECEIVER

KEY Input

SPINDLE_FG

POWER CONTROL

SENS,FOK,MIRR

MSDATO,DEFECT,DSP_SENSE,

SQSO,SQCK,SCOR,AO[0:5]

XLAT,S_CLK,S_DATA,DO[0:7]

PICK

UP

IC2A1

33P3721

RF Signal

Processor

IC205

DRAM

256K x 16bit

IC201

DVDSP-3301

CD/DVD DSP

DVD SERVO

IC501

SH7034

MAIN

u-COM

IC301

ZiVA-3

MPEG A/V

Decoder

IC305

SAA7126/8

VIDEO

Encoder

IC302

GM72V1621

1M x 16bit

SDRAM

IC303

GM72V1621

1M x 16bit

SDRAM

IC304

PLL1700

CLOCK

GENERATROR

IC2M1

KA3032

Motor Driver

POWER

BOARD

IC901

LC866112

OPEN S/W

CD DECK MECHANISM

CLOSE S/W

LIMIT S/W

M

M

DAC_LO,

S_CLK,

S_DATA

DA_DATA,

DA_LRCK,

DA_BCK

27MHz

X-TAL

L/R

VDATA[0:7]

Hsync

Vsync

IC306/307

BA7660

6dB AMP

AMP

VIDEO

'OUT

L/R

CVBS

Y

C

Y(G) PB(B) PR(R)

IC401/451

PCM1723E

AUDIO

DAC

3-13

2. Power(SMPS) Block Diagram

RECTIFIER(FLD)

RECTIFIER

LINE FILTER

SWITCHING TR

RECTIFIER(14V)

LPF

REG(8V)

REG(3.3V)

REG(3.3V)

PWR ON/OFF

F+

F-

-24VA

12VA

8V

5.2VA

5V_D

5V_A

3.3V

3.3V_M

2.5V

LPF

RECTIFIER(9V)

RECTIFIER(5.2V)

TRANS

LPF

FEED B.

3-14

IC2A1

33P3721

RF Signal

Processdr

IC206

DVDSP-3301

CD/DVD DSP

DVD SERVO

DRAM

256K x 16bit

IC2M1

KA3032

SpindleMotor,LoadingMotor,

Actuator Driver

PICK

UP

DVD:A,B,C,D,

FE,TE,PI,SBADD

SENS,FOK,SLD_FG,

MSDATO,DEFECT,DSP_SENSE

SQSO,SQCK,SCOR

XLAT,S_CLK,S_DATA

DSP_CS,/WR,/RD

DO[0:7]

AO[0:5]

DVD_DATA[0:7]

MCK

UCOM

I/F

MPEG

I/F

UCOM

I/F

M/D

DVD/CD RF

MIRR,TZC

ICADDR[0:8]

ICDATA[00:15]

MON,MDP

FDO,TDO,FMO

Spindle

focus,tracking,loading,sled

SPINDLE_FG

Load open/close(loading control)

CD:A,B,C,D/E,F

4

4

5

3

3

3

8

6

8

8

2

4

9

16

3. RF/CD DSP/DVD DSP/DVD SERVO Block Diagram

3-15

4. Audio Block Diagram

IC402

LPF &Buffer

NJM4580M

OP AMP

IC401

PCM1716

Audio DAC

U-COM

I/F

DAC_RST

S_DATA

S_CLK

DAC_L0

DA_LRCK

DA_BCK

DA_XCK

DA_DATA0

MPEG

I/F

A/V

JACK

I/F

L

R

L

R

3-16

5. MPEG Block Diagram

DSP

I/F

IC301

ZiVA-3

MPEG A/V

Decoder

IC303

GM72V1621

1M x 16bit

SDRAM

IC302

GM72V1621

1M x 16bit

SDRAM

IC304

PLL1700

CLOCK

GENERATROR

IC305

SAA7126/8

NTSC/PAL

Encoder

IC306

BA7660FS

6dB AMP

IC307

BA7660FS

6dB AMP

27MHz

X-TAL

U-COM

I/F

DVD_DATA[0:7]

DAI_DATA

DA_DATA[0:3]

DA_BCK,DA_XCK,DA_LRCK

SPDIF

HSYNC,VSYNC

CVBS

Y

C

Y

PB

PR

CVBS

AUDIO

I/F

A/V

JACK

I/F

U-COM

I/F

U-COM

I/F

SERVO

I/F

Y

C

Y

PB

PR

VDATA[0:7]

DA_XCK

MPEG_CLK

IIC_DATA,IIC_CLK

IIC_DATA,IIC_CLK

DAC_RST

8

SDCLK1,ZISENB

REQZ1

2

2

A[00:02]

D[00:07]

MPEG_ERROR

MPEG_RST

DVD_SD_CS0,DVD_UDQM

DVD_MD[0:15]

DVD_MA[0:11]

DVD_SD_CAS

DVD_SD_RAS

DVD_SD_CLK

DVD_MWE

DVD_LDQM

DVD_SD_CS1

S_CLK,S_DATA

版权声明

1. 本站所有素材,仅限学习交流,仅展示部分内容,如需查看完整内容,请下载原文件。

2. 会员在本站下载的所有素材,只拥有使用权,著作权归原作者所有。

3. 所有素材,未经合法授权,请勿用于商业用途,会员不得以任何形式发布、传播、复制、转售该素材,否则一律封号处理。

4. 如果素材损害你的权益请联系客服QQ:77594475 处理。